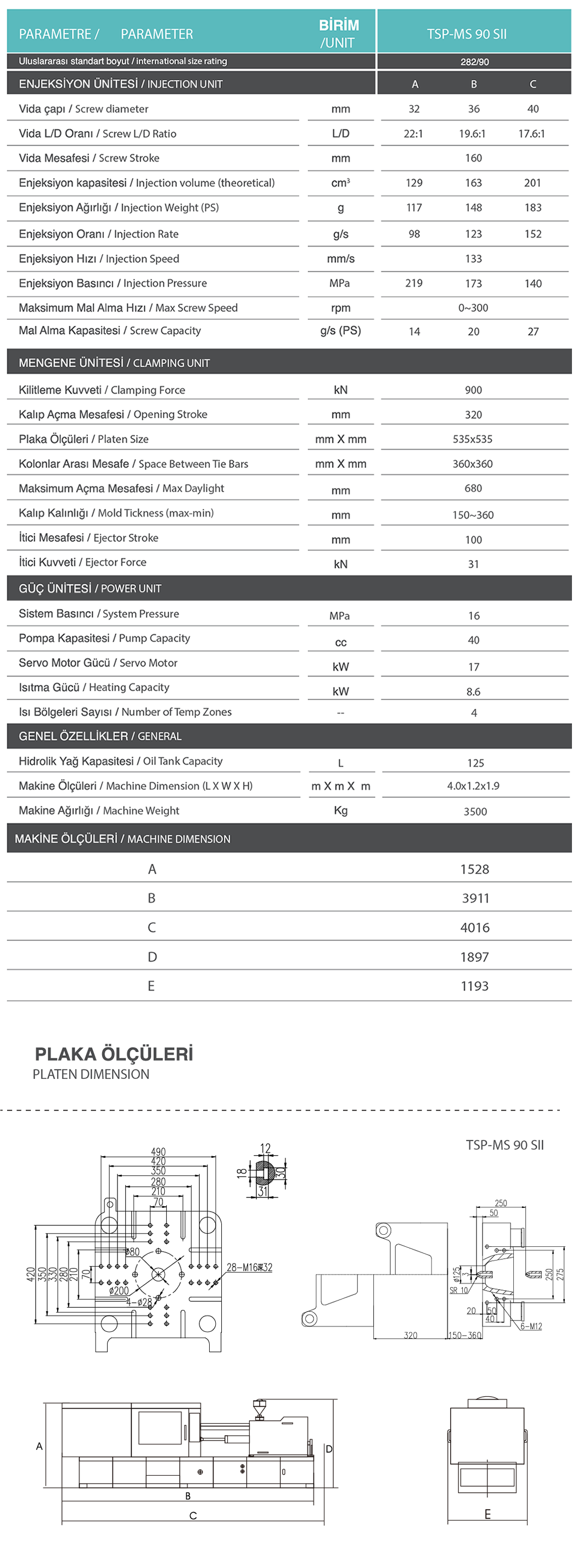

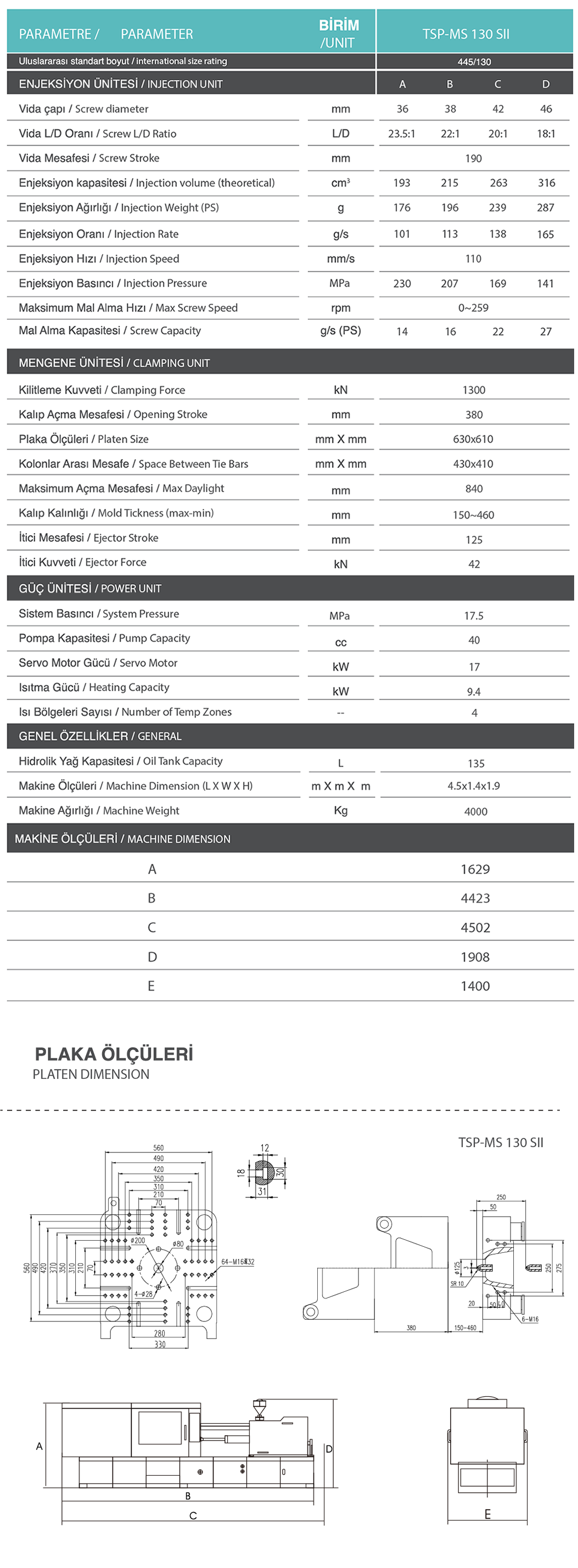

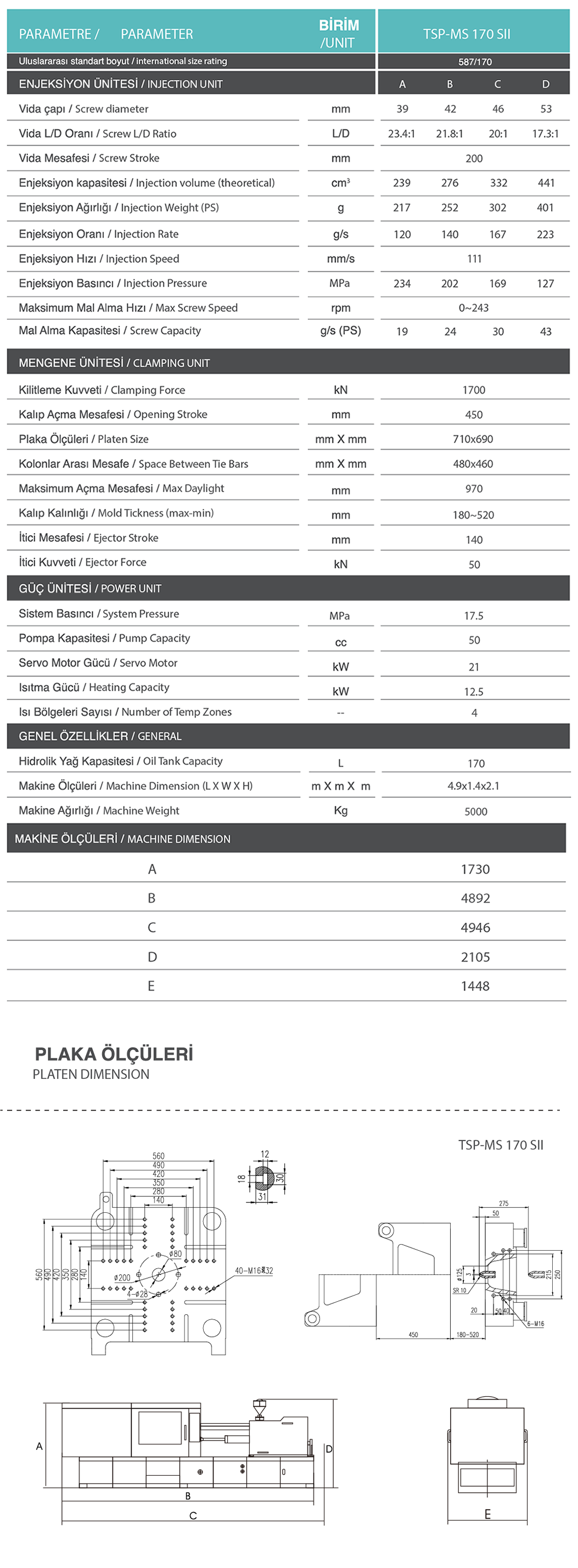

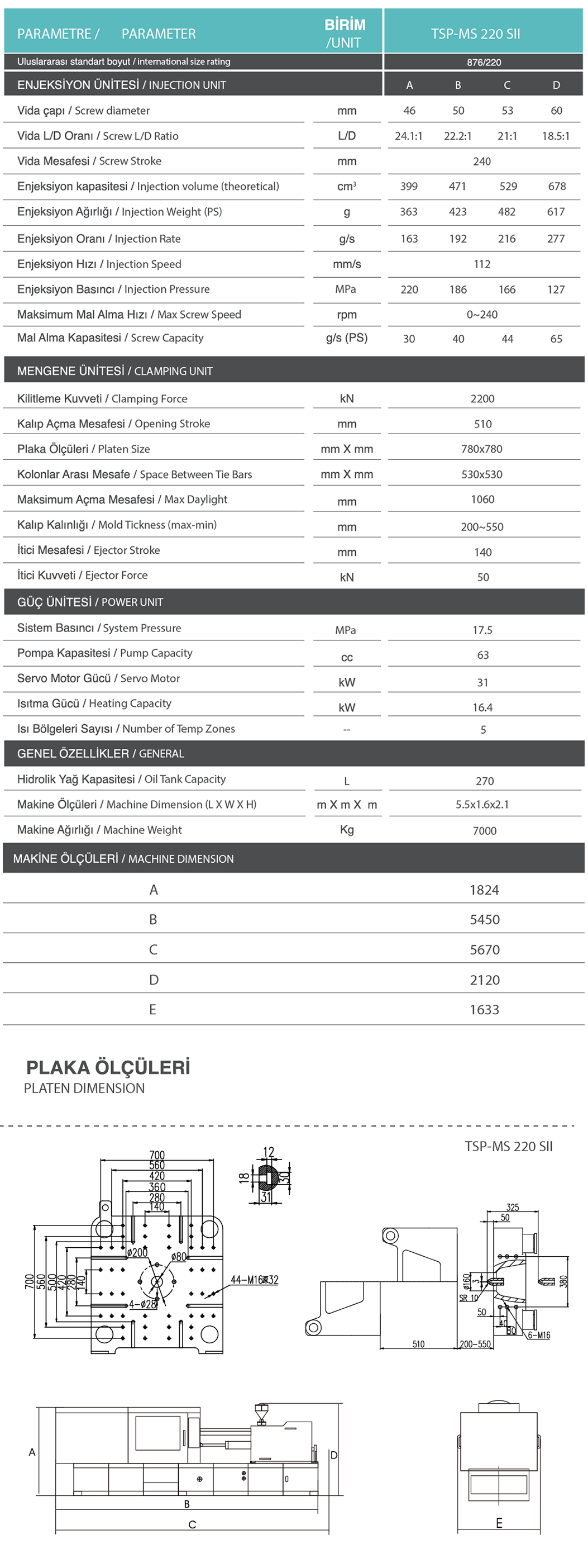

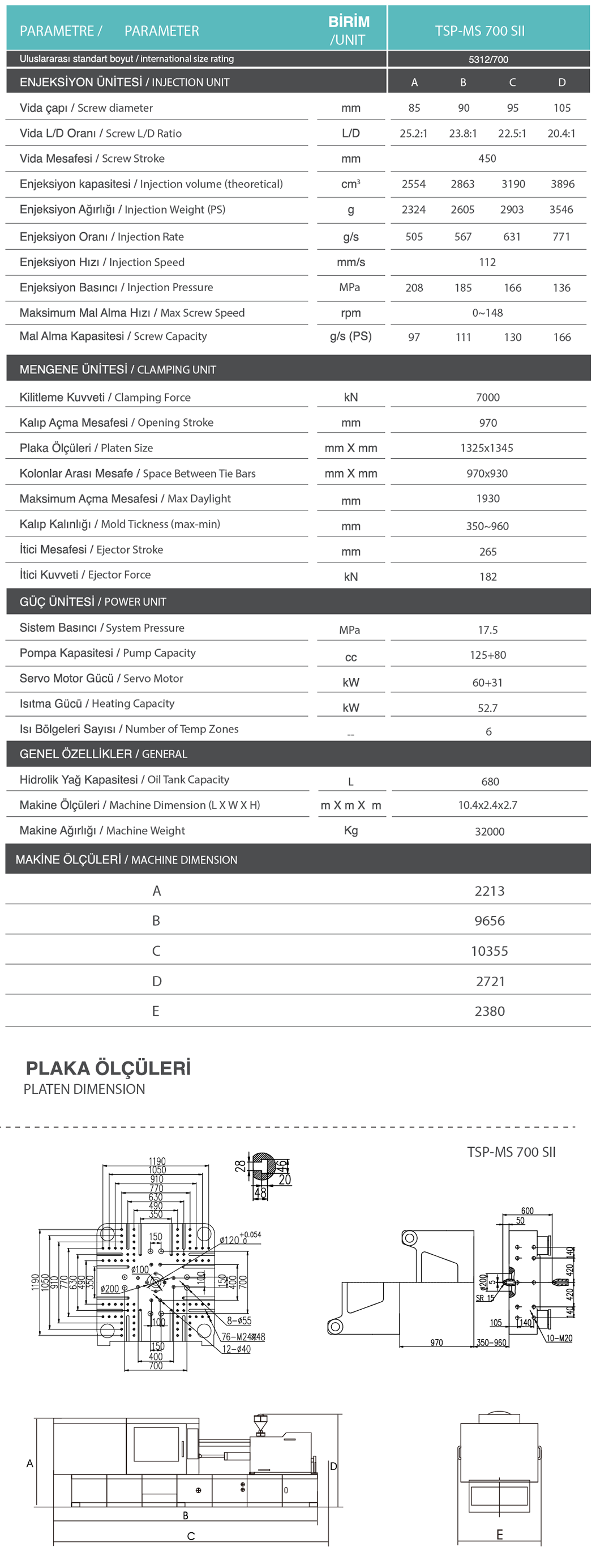

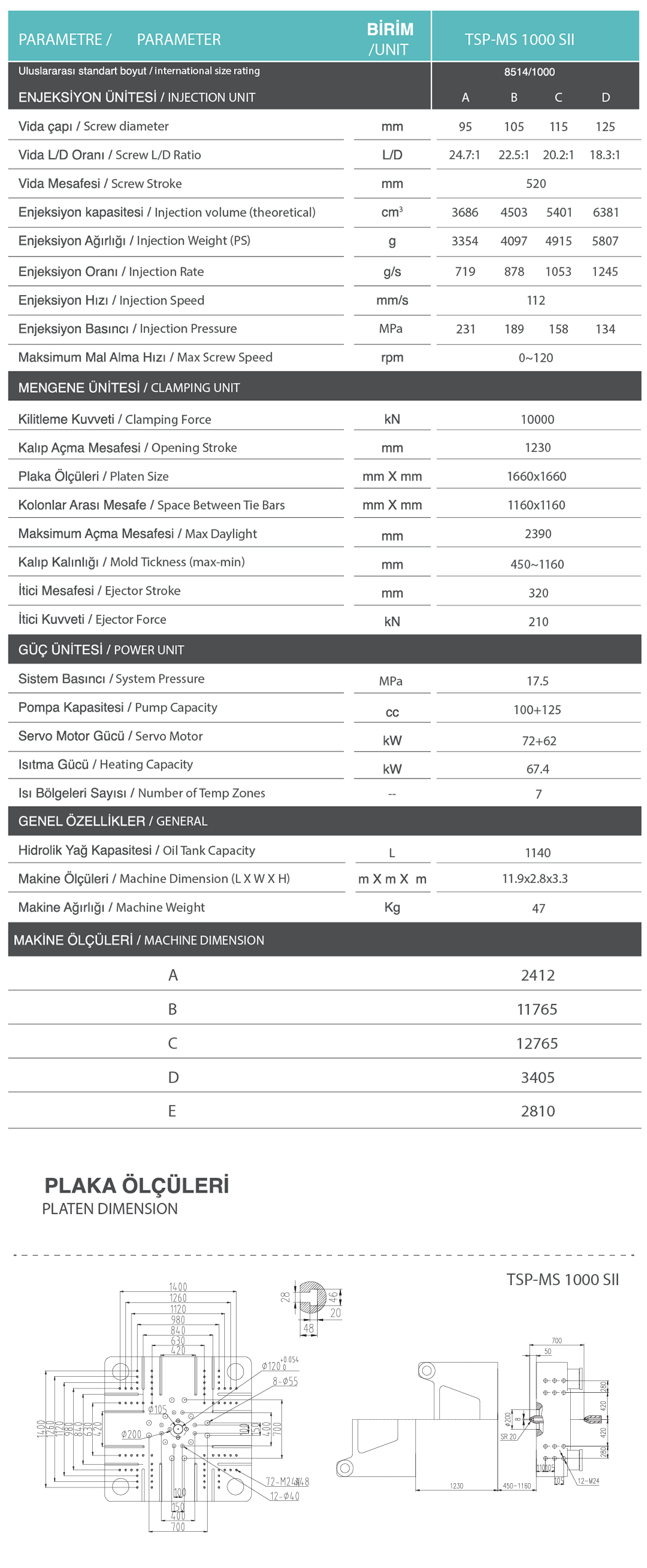

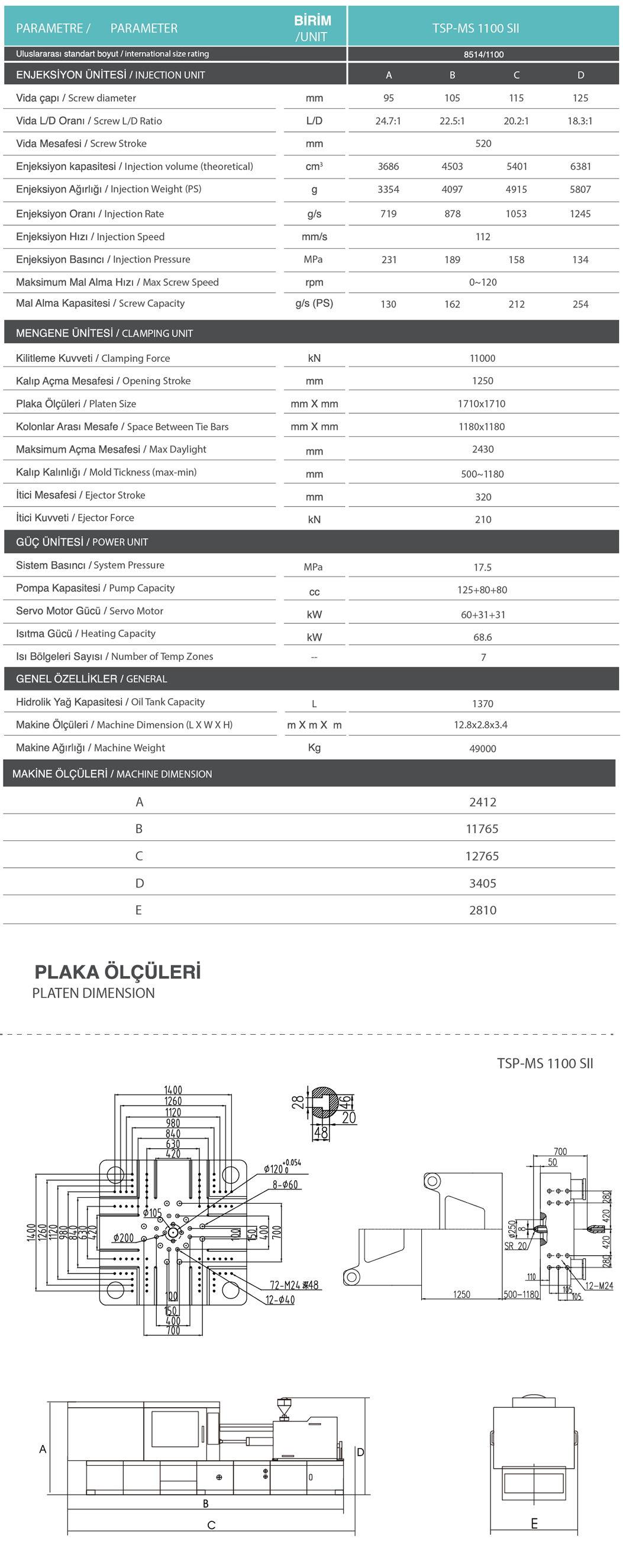

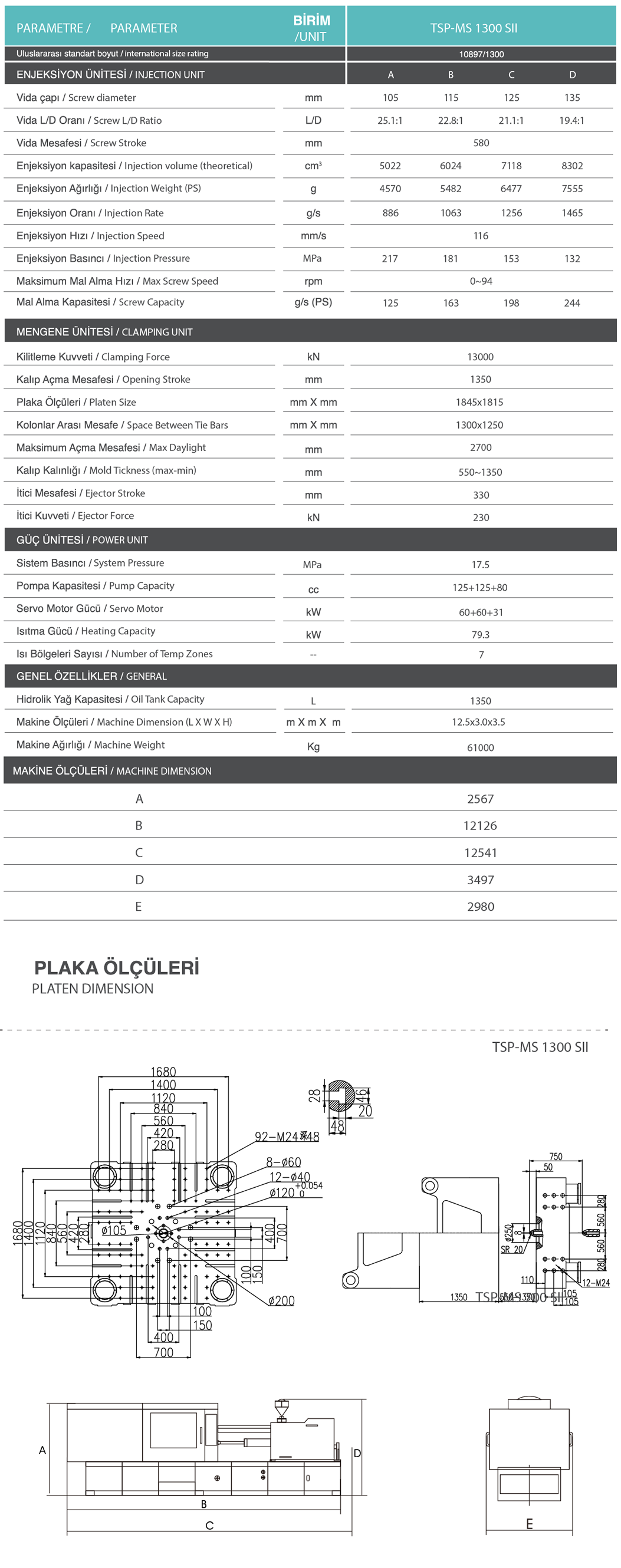

Our MS-SII Series machines, featuring superior technology, offer a wide tonnage range from 90 tons to 3300 tons.

The hydraulic motor drives the automatic mold adjustment device, ensuring stable, fast, and efficient operation. This results in significant time savings during mold clamping.

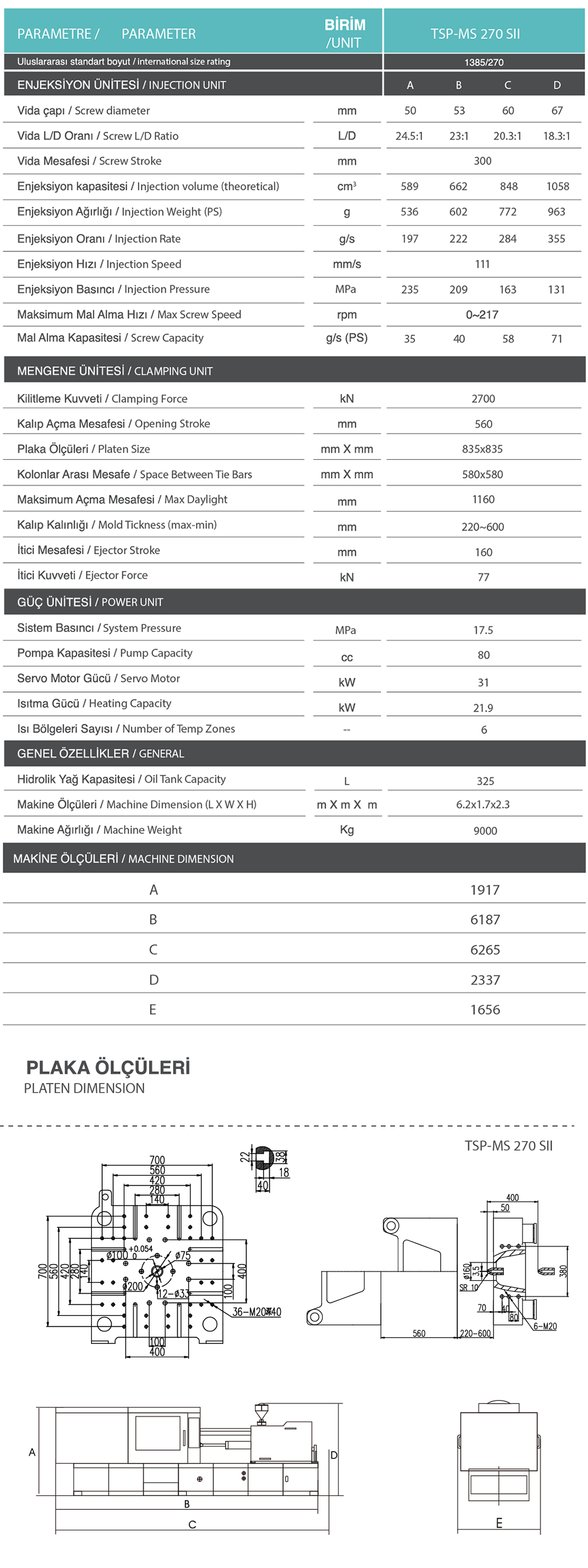

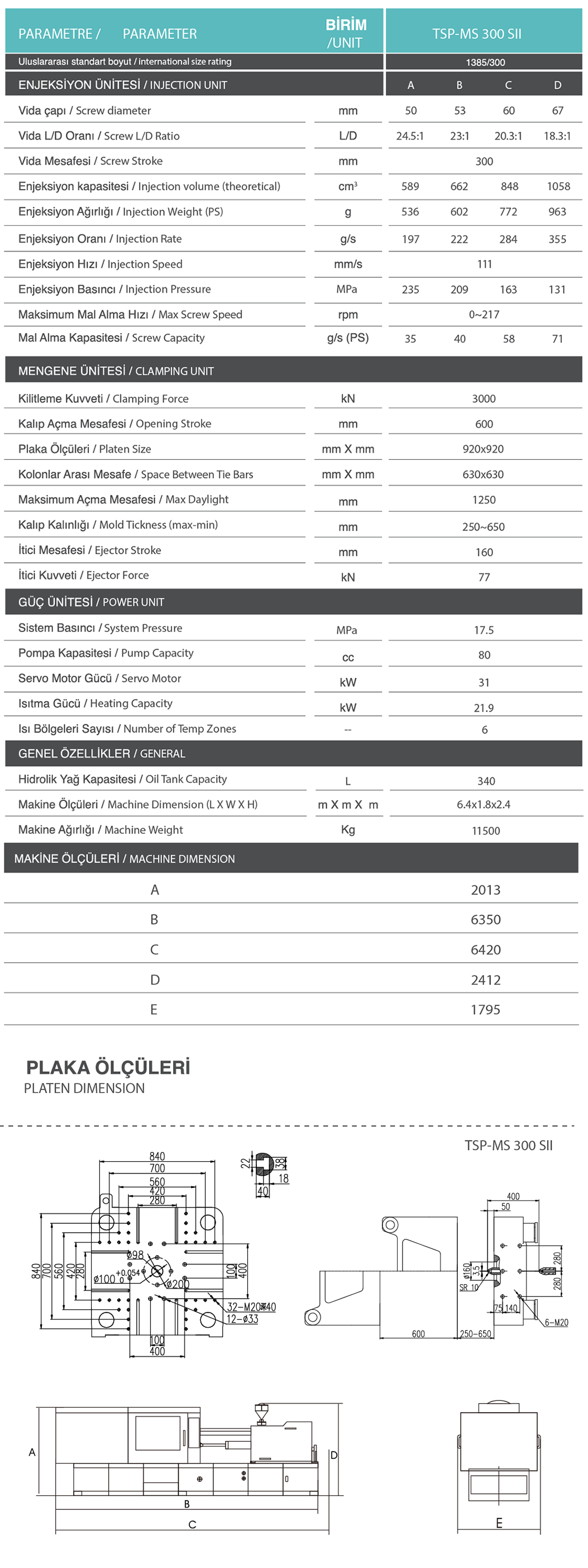

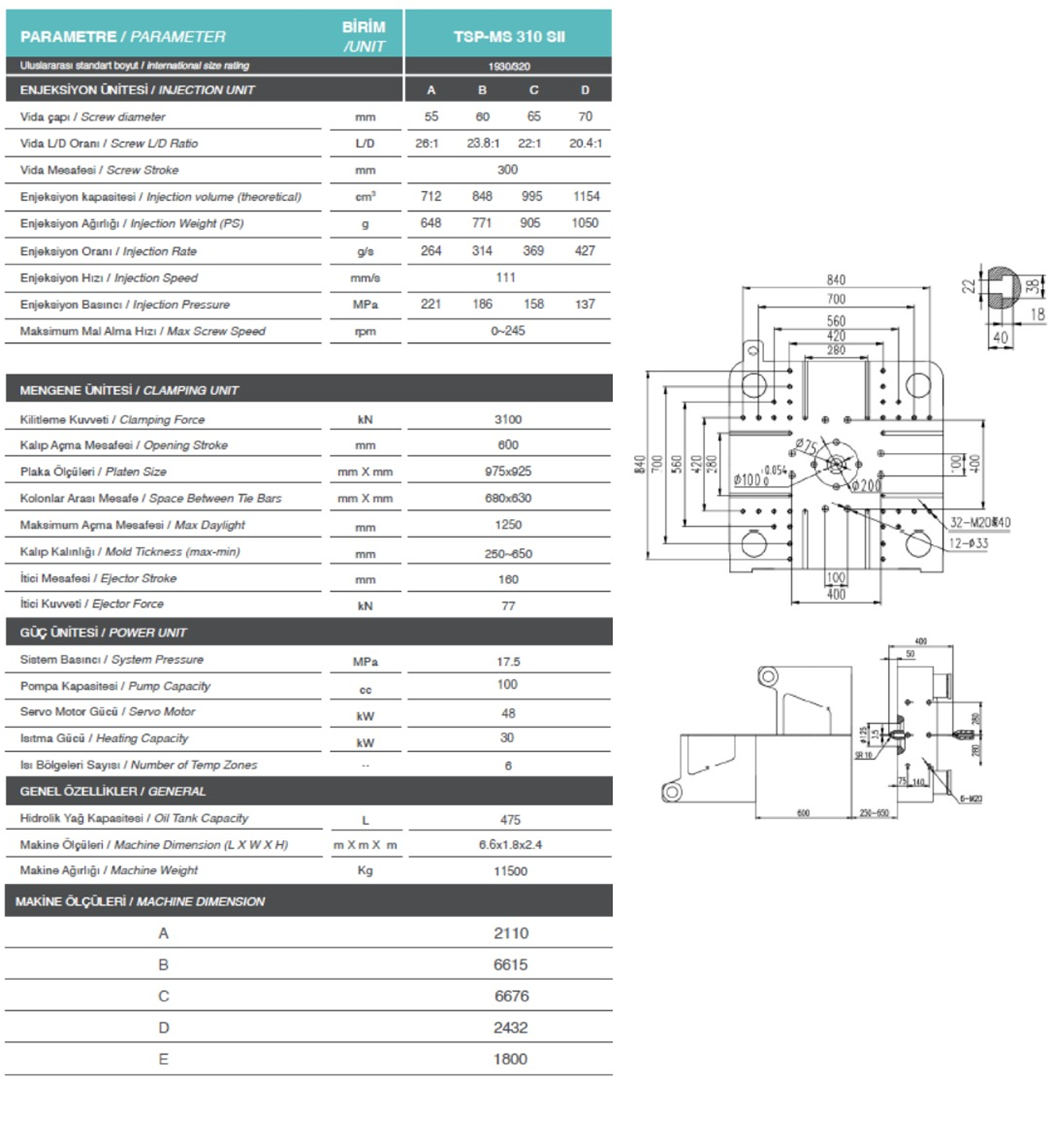

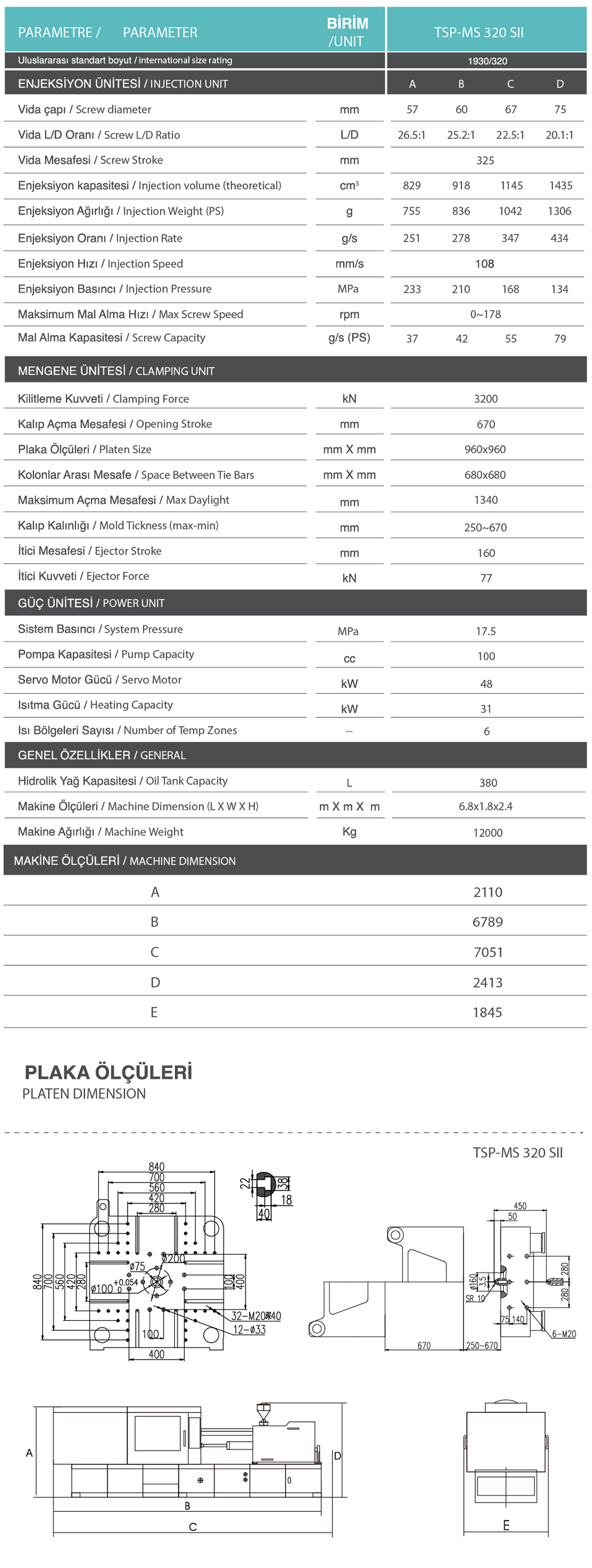

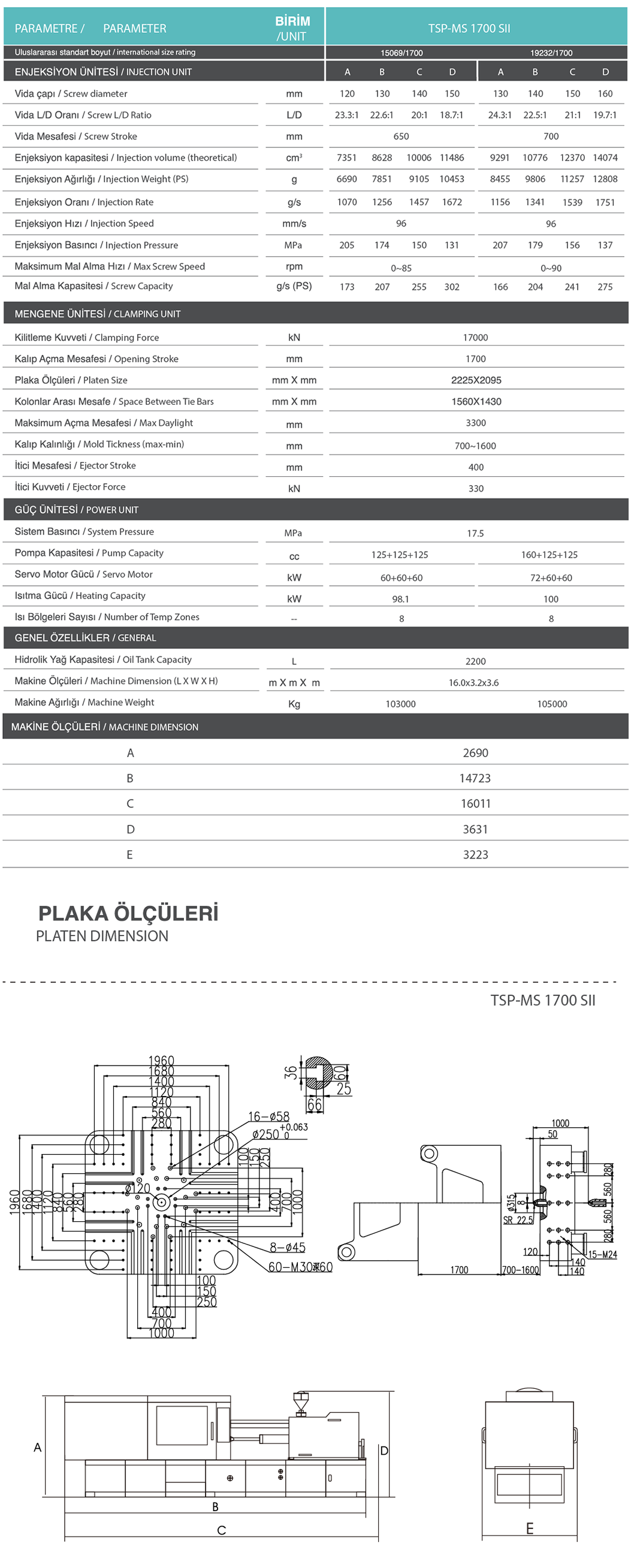

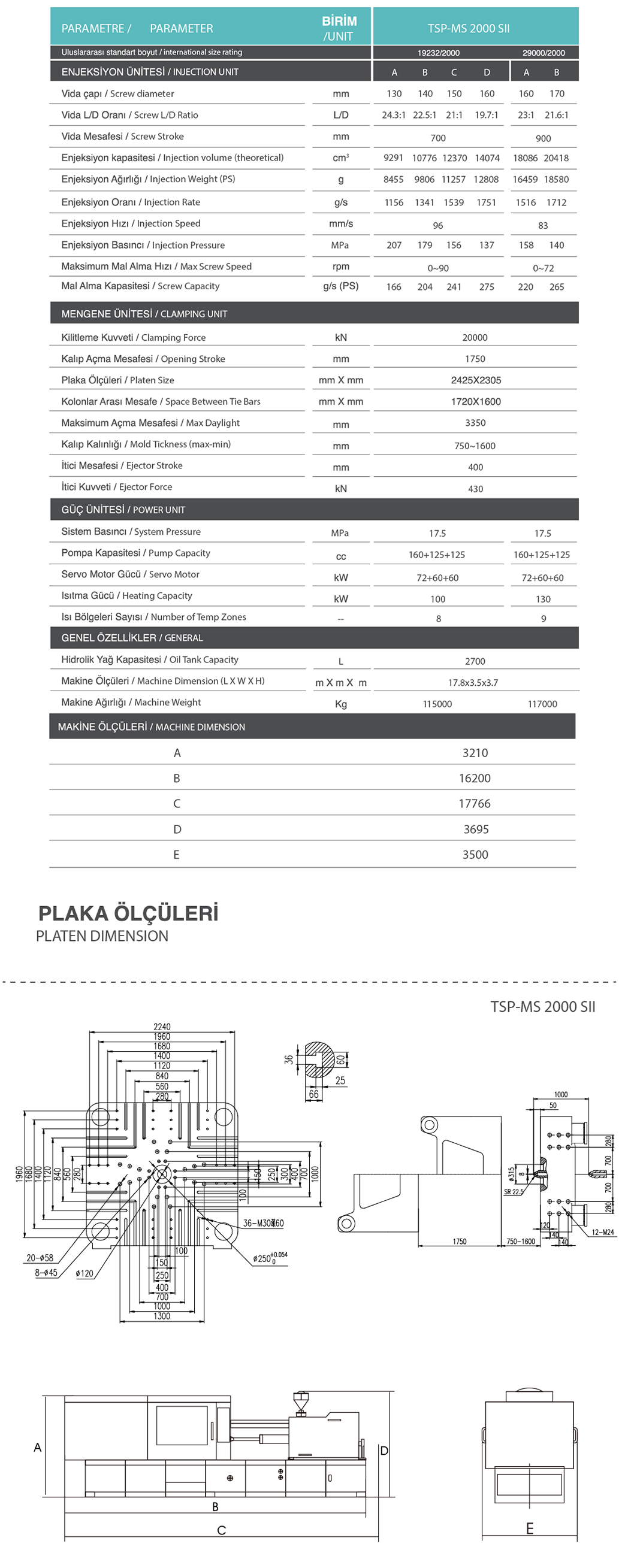

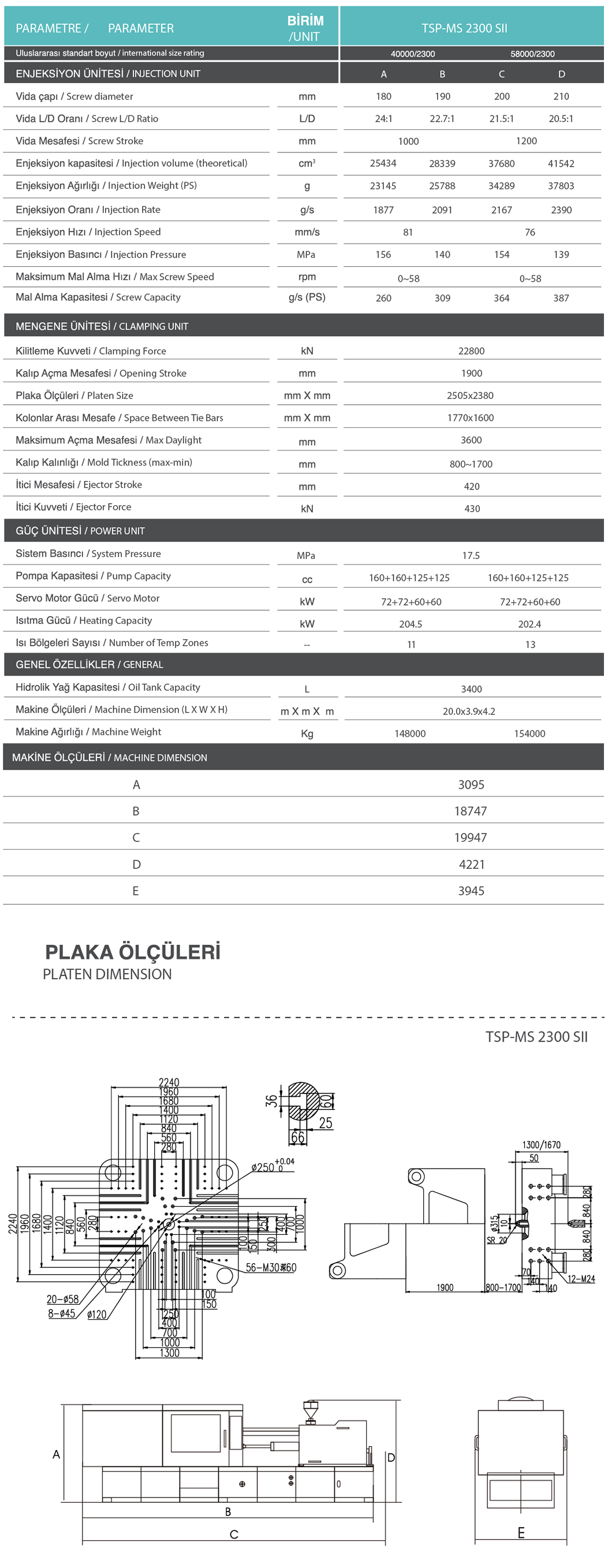

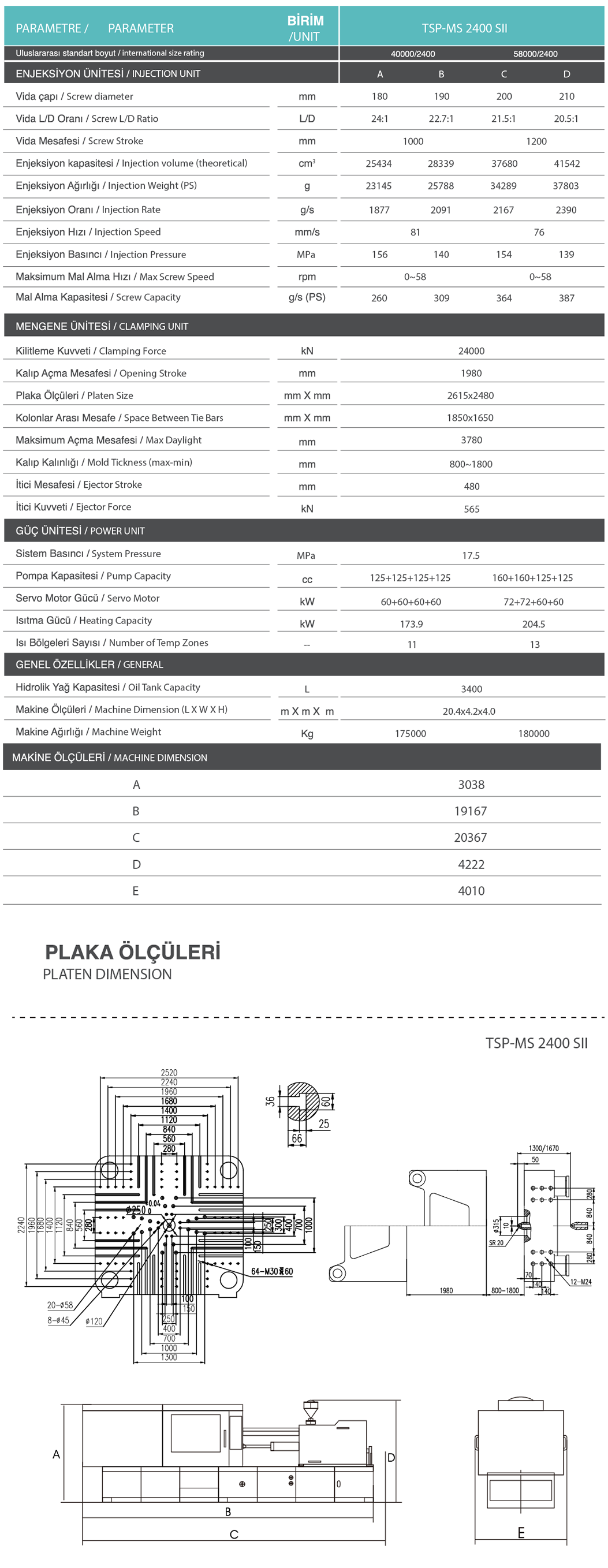

Improved Plasticizing Capability and High Performance with an Optimized Screw and Barrel DesignThe machine features a double-cylinder injection system, double guide cylinders, and a low-resistance linear guide design for more stable and precise injection movement. This high injection precision enables faster injection and provides controlled back pressure during charging.

The optimized screw and barrel design provides more powerful plasticizing capability and better performance to accommodate various types of specialized products.

In addition, key components such as the injection carriage and coupling have been reinforced to significantly reduce the risk of piston rod fracture.

High Precision, Energy Efficiency, Fast Response. The synchronized servo motor and drive, with its digital closed-loop control, provides superior energy efficiency and savings, a fast response, and precise controls. The system is also more stable at low flow rates.

The MS-SII series is equipped with a high-performance controller that features a large LCD screen and a simple, user-friendly interface.

Designed in accordance with GB2530 national safety standards, the machine comes equipped with a standard safety relay, a hydraulic safety valve, and a protective metal cover.

To further enhance the machine's overall safety performance, it features components from imported brands such as Schneider, ABB, and OMRON, including a thermal main circuit breaker and 5-pin outlet protection.