Developed specifically for plastic injection processes, Wemo robot systems combine speed, precision, and safety to make production lines intelligent, flexible, and efficient. Designed with Swedish engineering, these automation solutions shorten cycle times, increase workforce efficiency, and reduce operator intervention. Trusted by thousands of manufacturers worldwide, Wemo provides a reliable and sustainable solution partner to modern plastics producers.

Wemo offers one of the widest ranges of automation solutions for the plastics industry. Our linear robots are manufactured in Sweden and are top-of-the-line within their class. When you invest in a linear robot solution from Wemo, you get the following advantages:

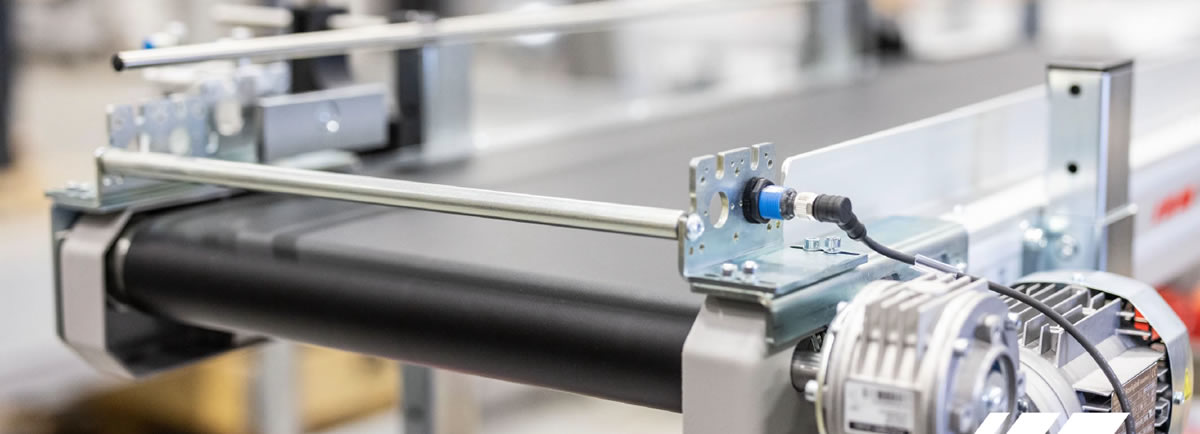

Wemo Conveyor System

(Belt conveyors and Box transport systems)

A production cell is only as strong as its weakest link. Therefore, based on our long experience in automation, we have chosen to develop and manufacture our own belt conveyors.

Wemo Gripping System

Standardized components, designed by users, for users.

The gripping system makes it easy to create an end-of-arm tooling.

Our simple and modular standard component system simplifies the often-complex process of adding new components to your production.

Wemo Safety System

(Smart protection system around your automation)

The Wemo safety guard is a complete machine protection system that can be quickly and easily integrated into your automation.

Additionally, it complies with the requirements of the 2009 Machinery Directive regarding permanent guards.

Wemo SmartDrive 2.0

(Servo linear axes)

The WemoSmartdrive 2.0 design is based on our long experience in material handling within robotic cells. It provides a high transport capacity at high speeds, while maintaining precise positioning and repeatability.

Our highly dynamic mechanical systems, equipped with an integrated energy chain, are available in various sizes and strokes. On all axes, planetary gearboxes are used as standard for highly efficient output.