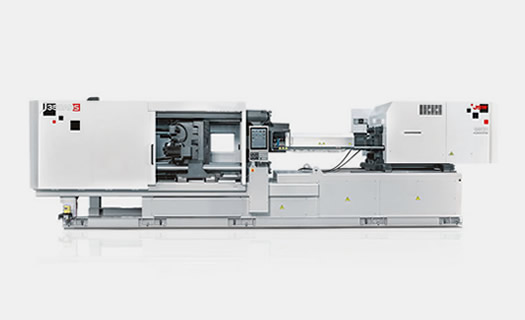

Our new generation, all-electric injection molding machines are available with clamping forces from 30 tons to 3000 tons as standard products. JSW all-electric injection molding machines offer 30-70% electricity savings and 55-75% improvement in cycle times compared to hydraulic machines.

SYSCOM Controlled Terminal

Signals are processed at ultra-high speed, and the high degree of repeatability in process parameters leads to shorter cycles and increased productivity.

Thanks to the 15" TFT color touch screen, you can get an exceptionally detailed view of injection parameters and real-time display of data and graphics.

Menu areas for easy parameter entry. Support and explanation texts are available via selection fields.

Uniform application interface for all models.

Backup of data on an internal memory or an external USB stick.

SPC analysis function.

Precise quality control and alarm management.

Stronger Clamping Unit

Thanks to its stronger clamping unit, it ensures production efficiency and quality.

Wide Selection Range

Ensuring product quality (incorporates the fastest servo control circuit in its class in the industry with 62 microseconds).

Different core pull valve options can be installed. Pneumatic, electric, servo-electric, or hydraulic (via an additional hydraulic system).

Extraordinarily precise PID setting for barrel temperatures (± 0.1°C). Cylinder structure is N2000F bimetallic type. The screw is protected against wear and corrosion (Type LSP2, standard up to -18H).

Highly rigid fixed and moving platens to ensure optimal platen parallelism. The hole pattern on the platens complies with EUROMAP 2.