The TSP PET high-speed preform injection system is built upon the TSP MSII series design platform and Xiao Cheng's core concepts of precision, satisfaction, stability, and speed.

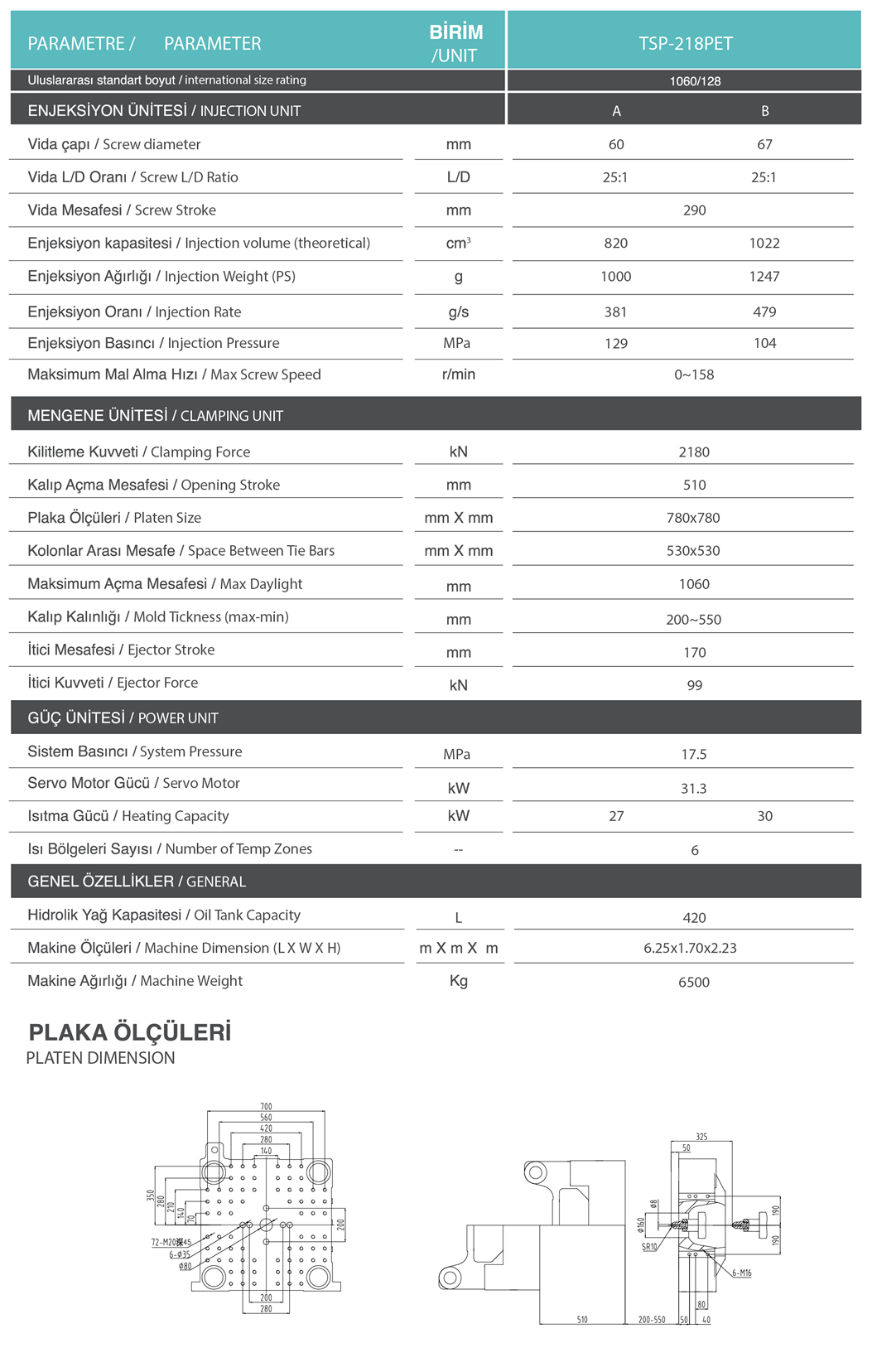

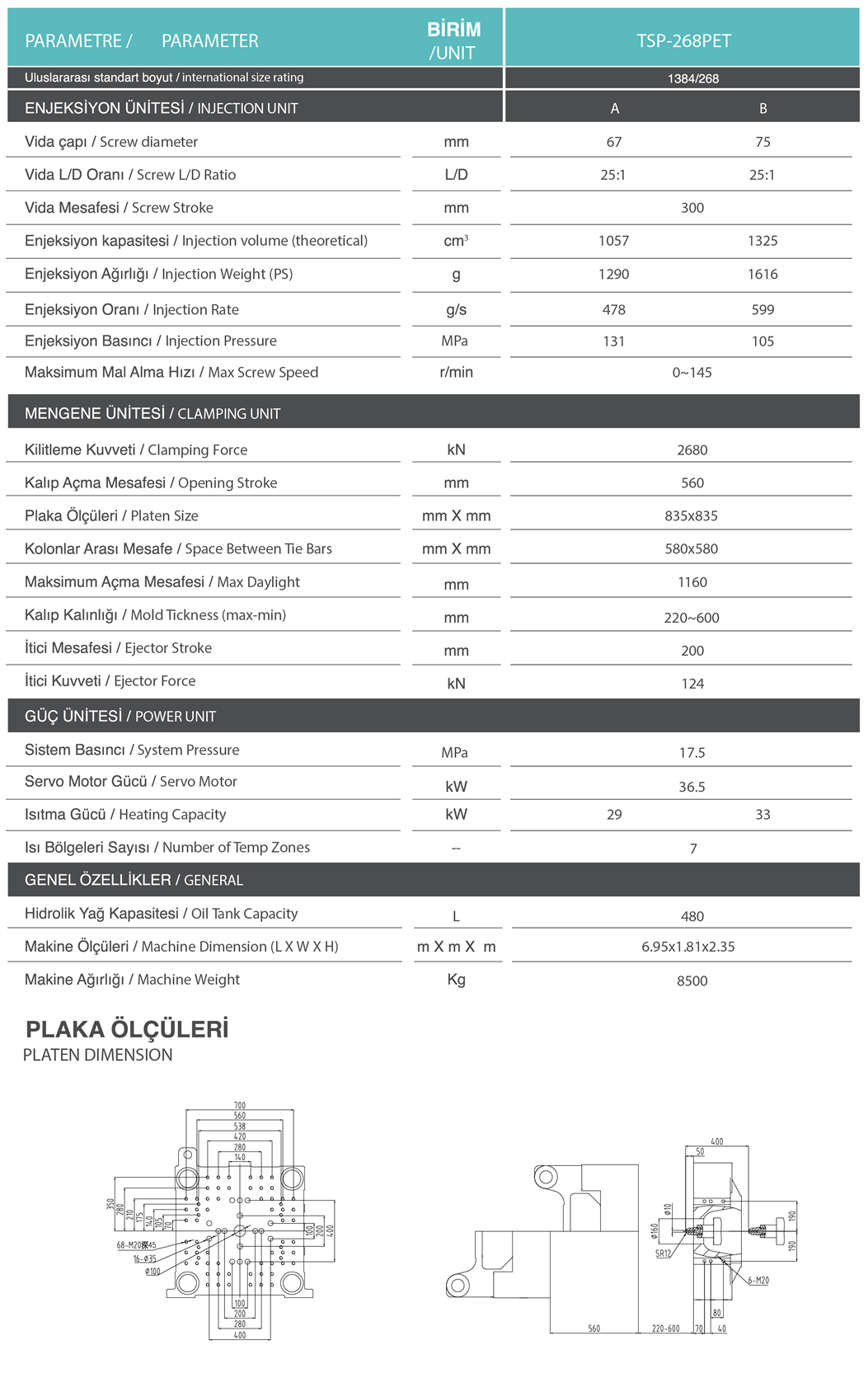

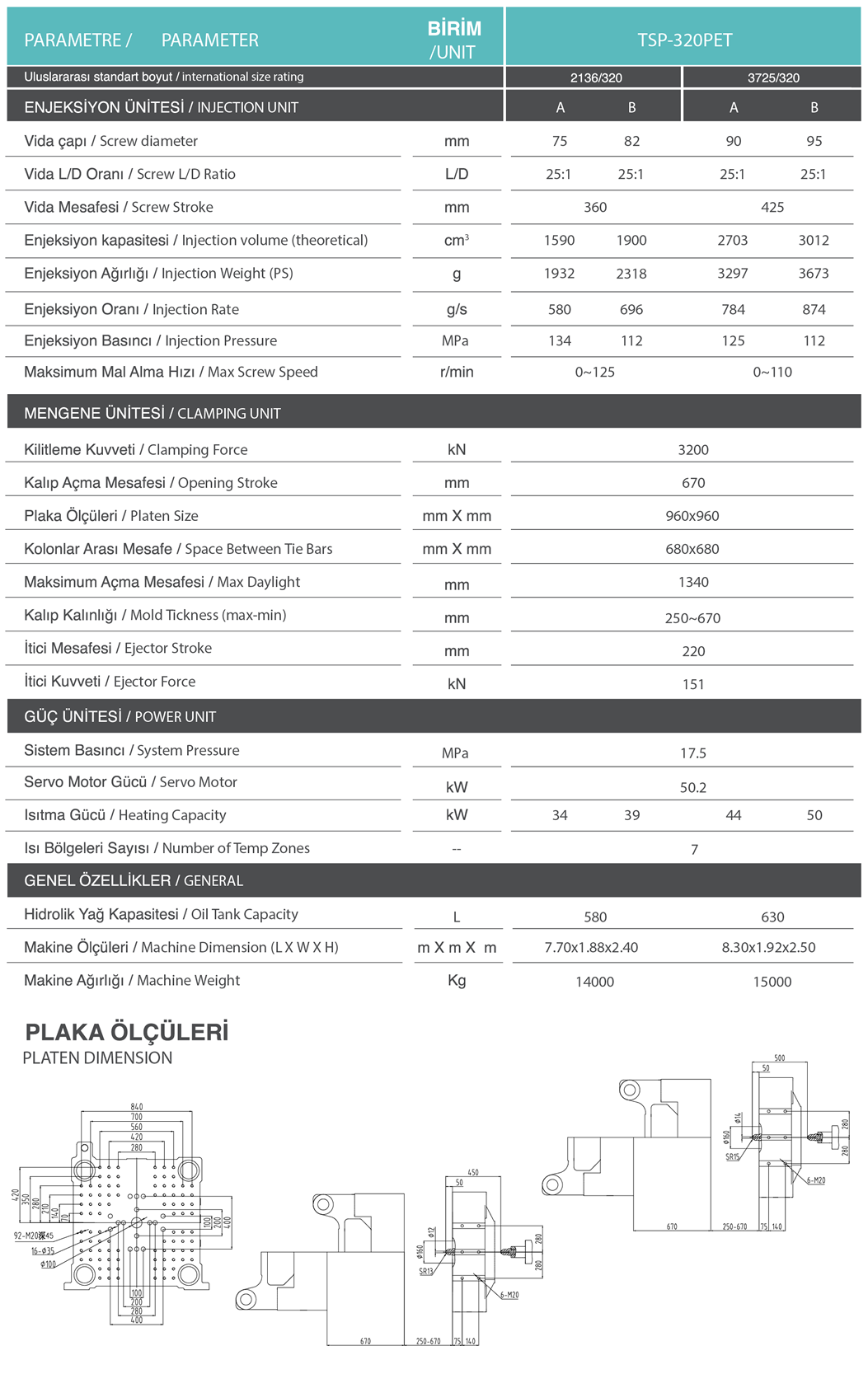

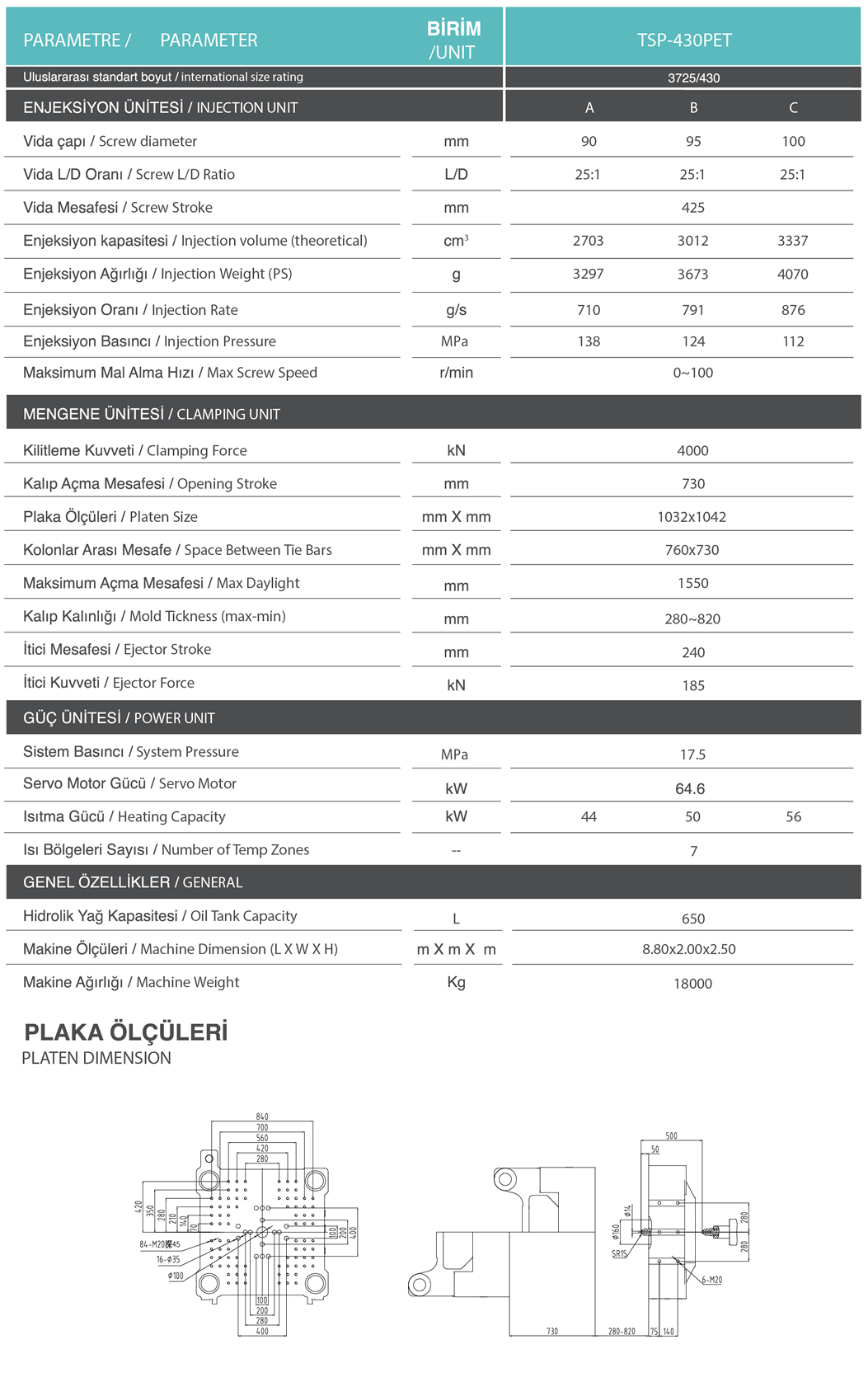

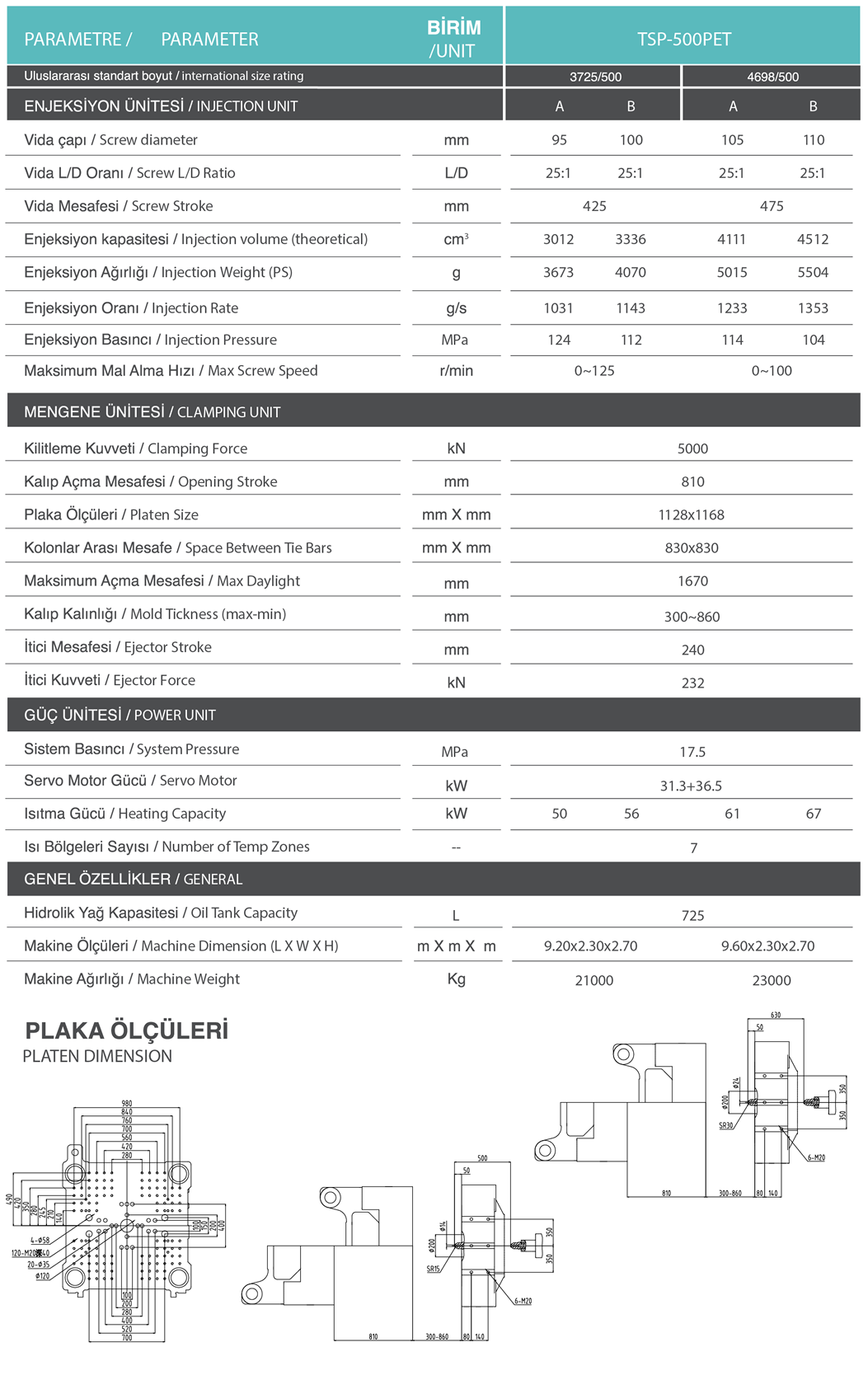

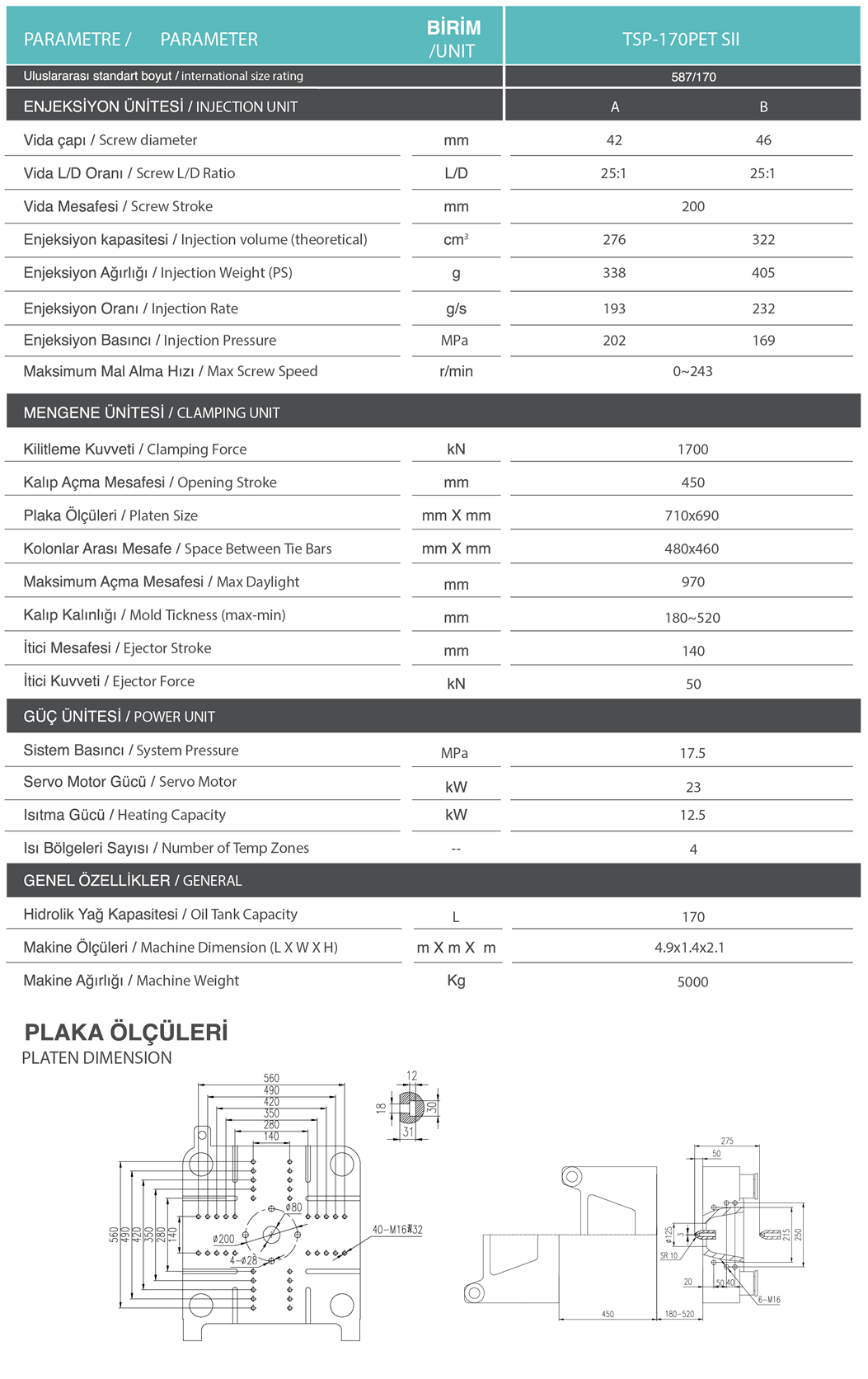

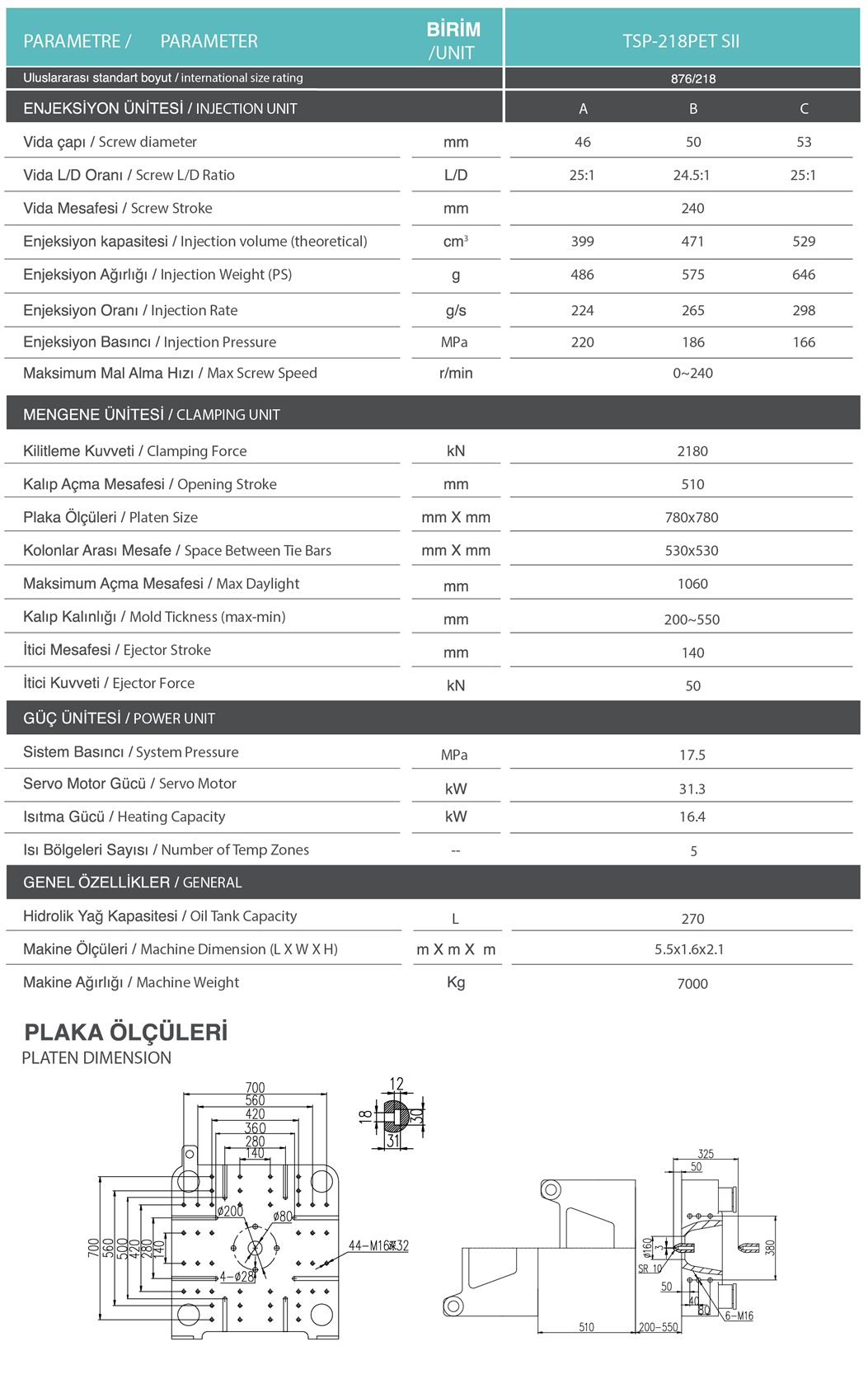

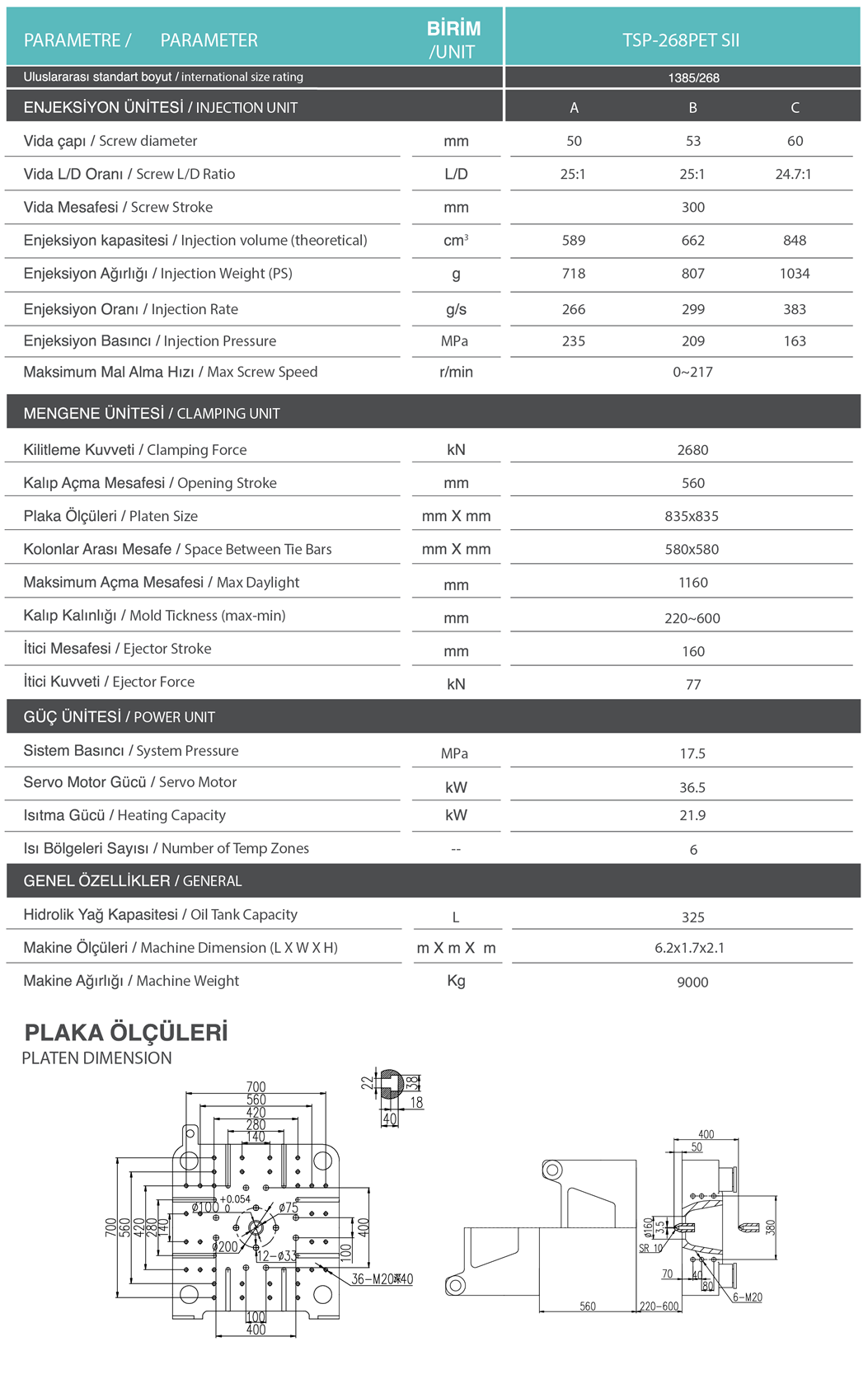

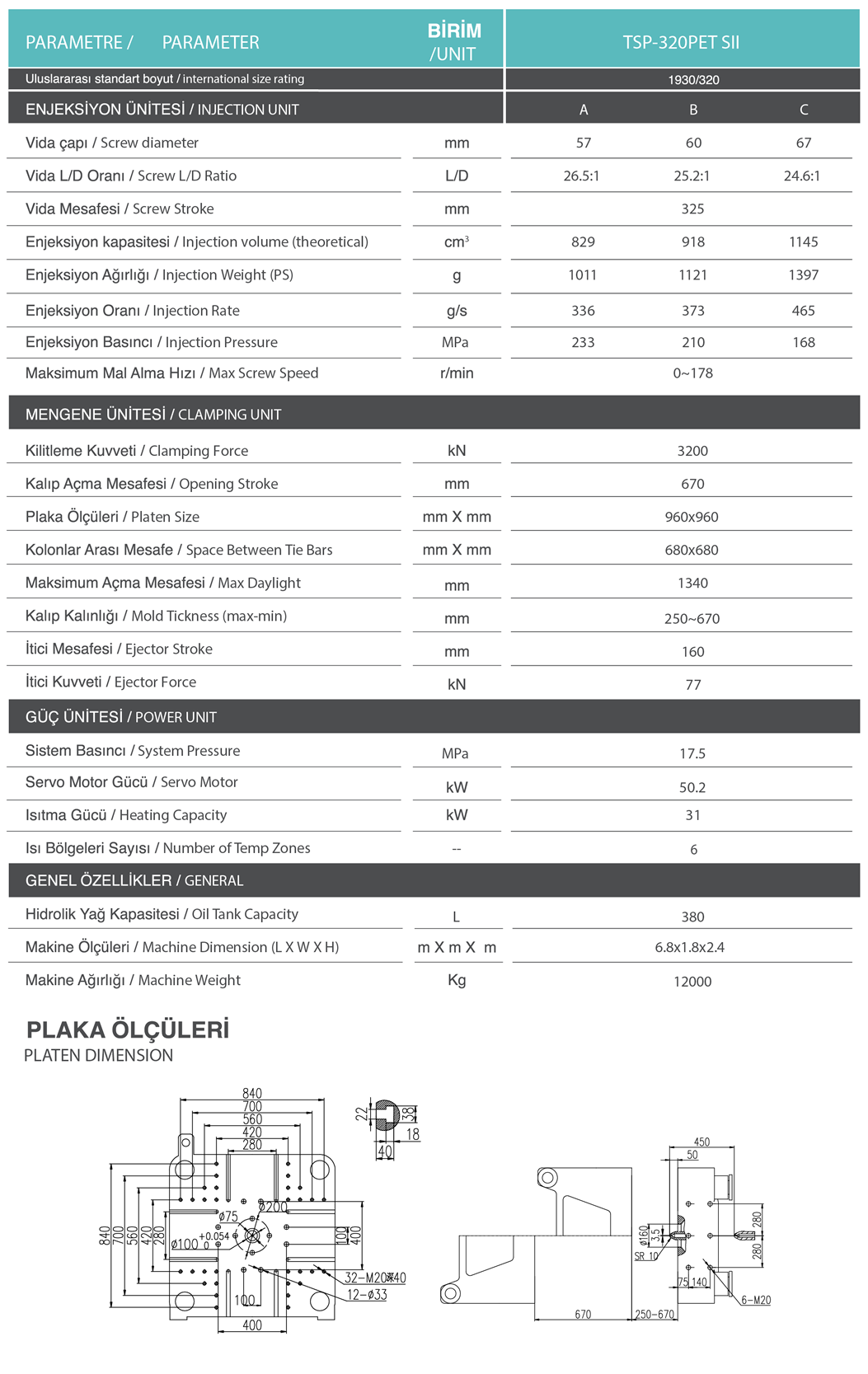

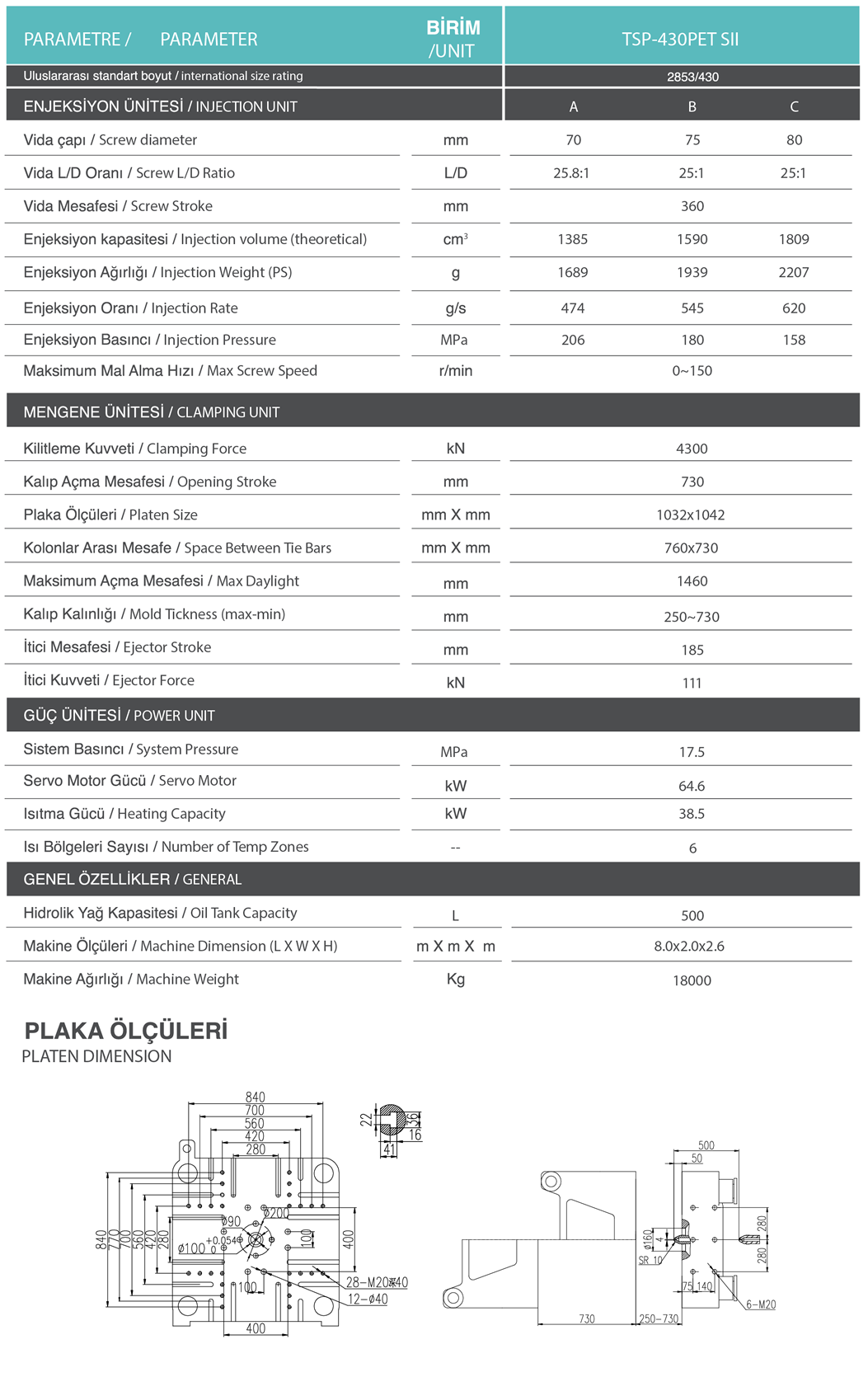

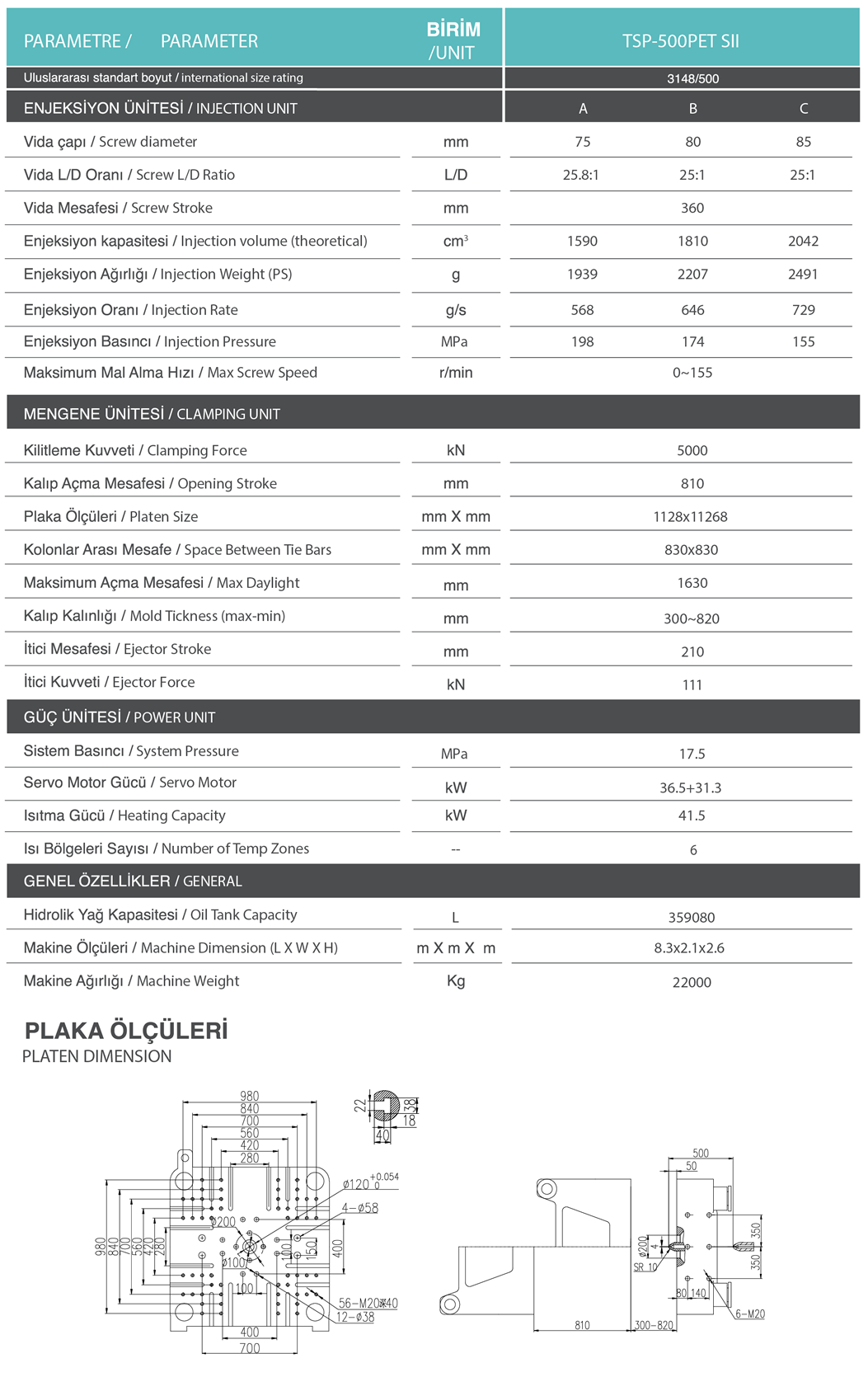

The newly designed clamping system, with its high-rigidity structure, helps reduce deformation defects while providing stable and efficient performance.

The generous opening stroke and mold thickness enable widespread use in the production of plastic preform molds of various sizes.

The injection platform features a fully integrated injection cylinder and a double-cylinder system to ensure a more stable and balanced injection. This design significantly reduces oil return resistance during high-pressure operation, leading to a more consistent and stable injection process.

The optimized linear guide design is integrated into the injection unit to ensure stable, even movement and coaxial force during injection.

This design increases the rigidity of the mechanism, resulting in a more precise and balanced injection process. Furthermore, the linear guides are used to minimize friction resistance during both injection and plasticization, which effectively increases the hydraulic system's response speed.

To ensure plasticization stability and a long service life, the machine uses a specially reinforced and enlarged hydraulic motor. This motor is equipped with a back oil discharge and self-lubricating functions for optimal performance.