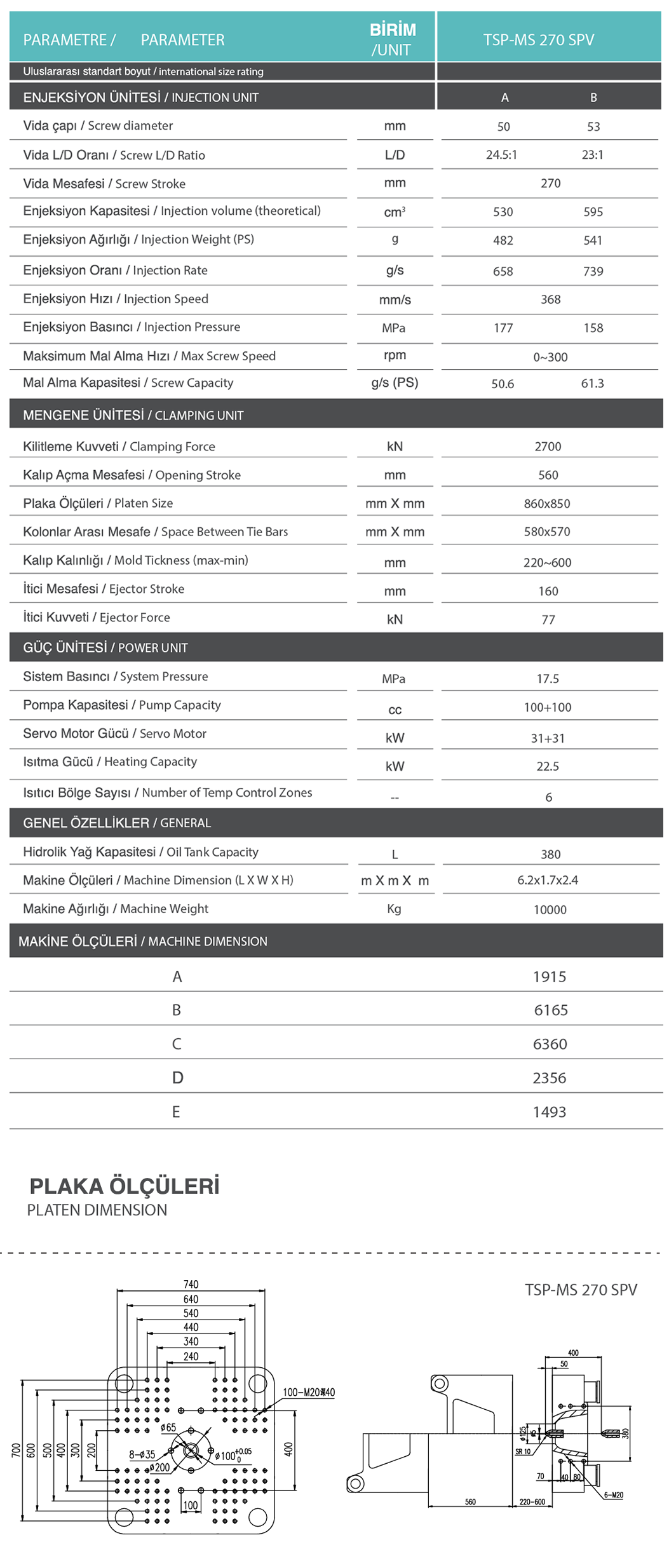

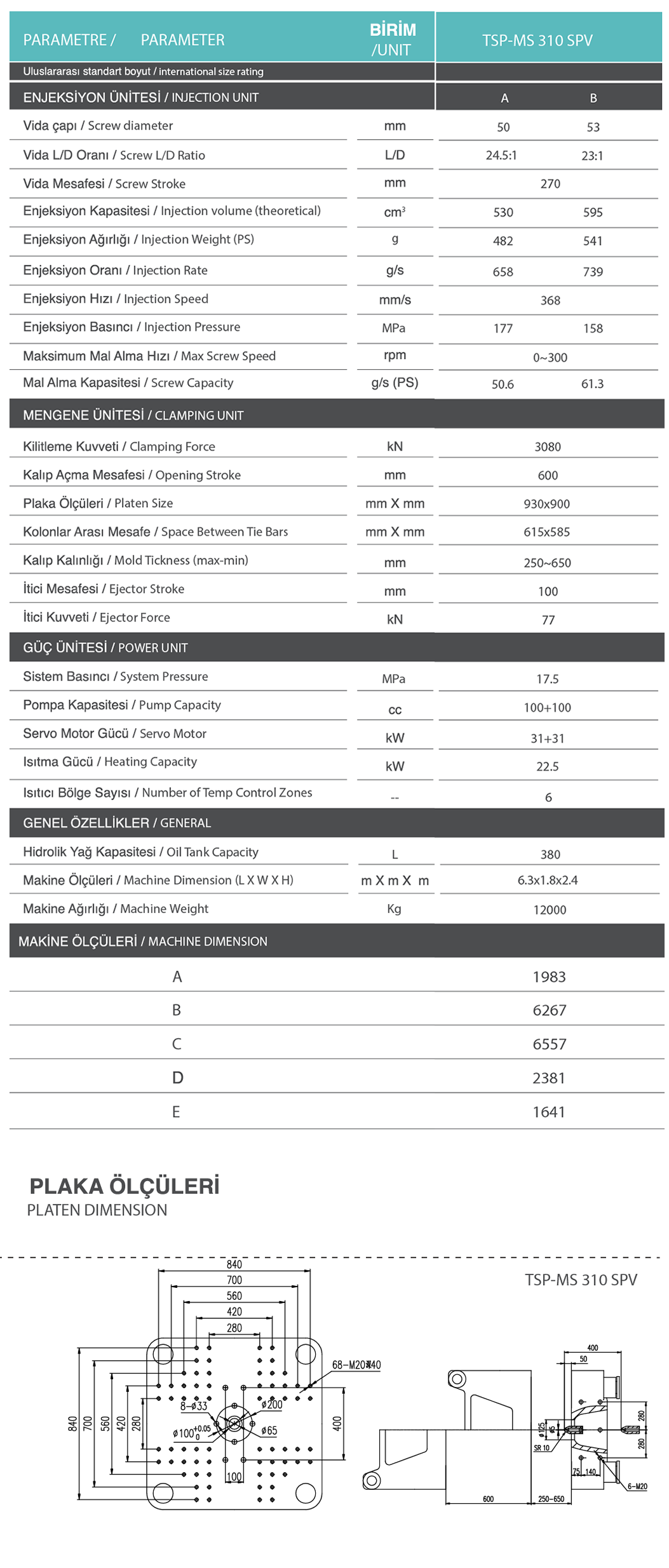

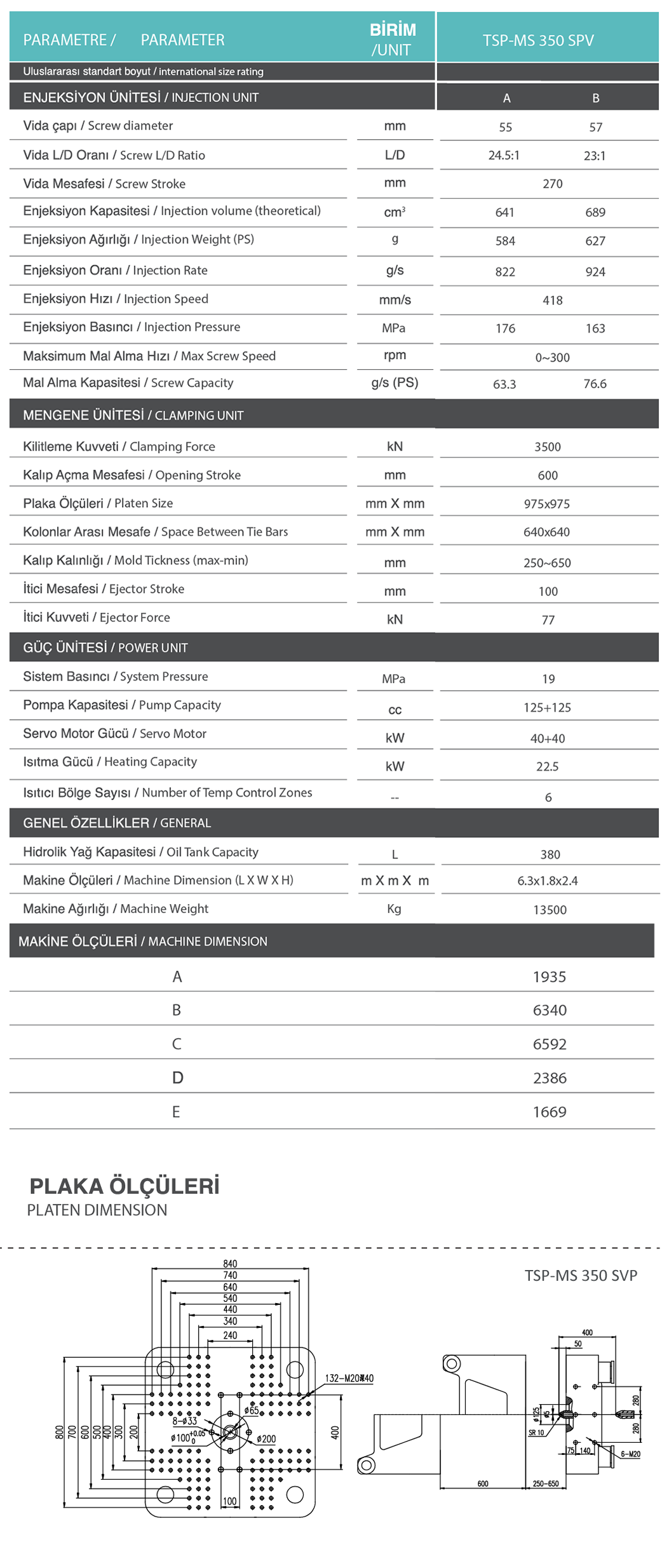

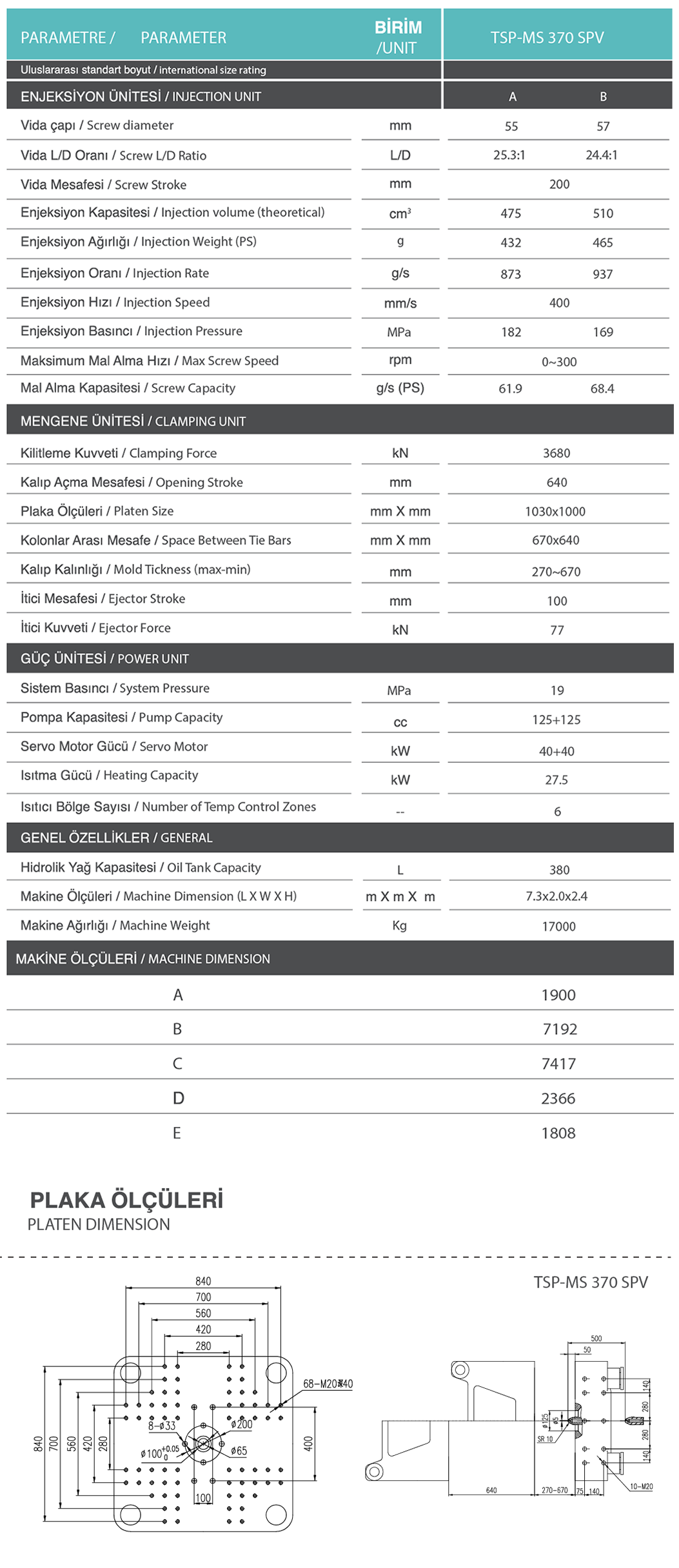

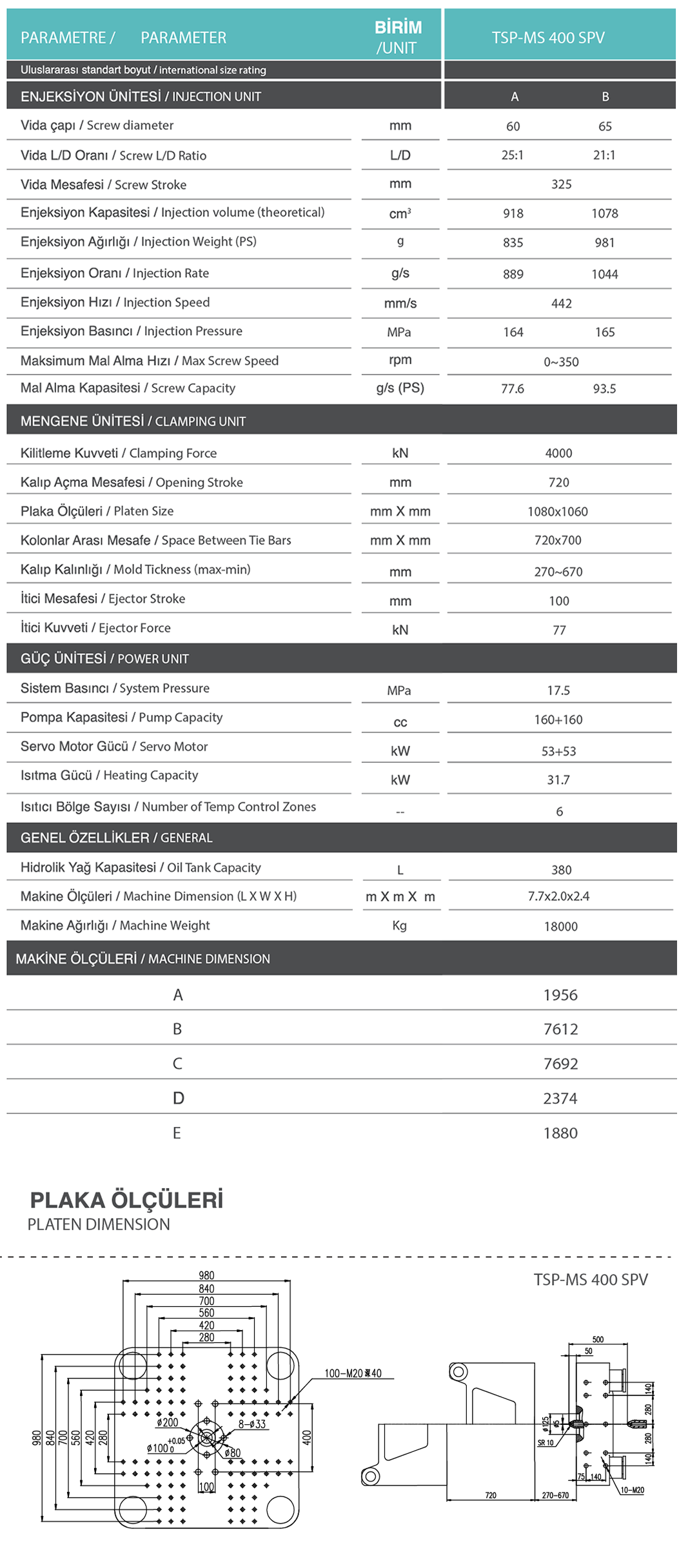

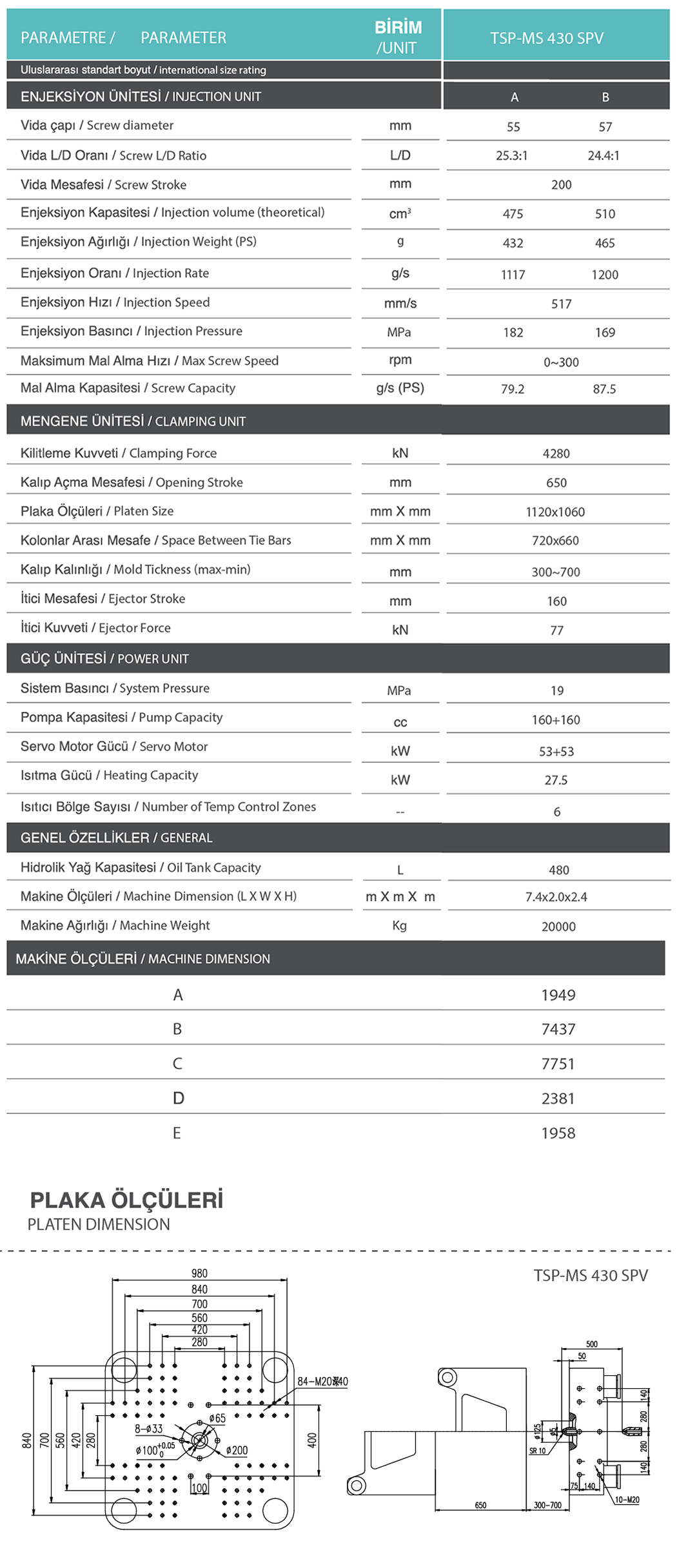

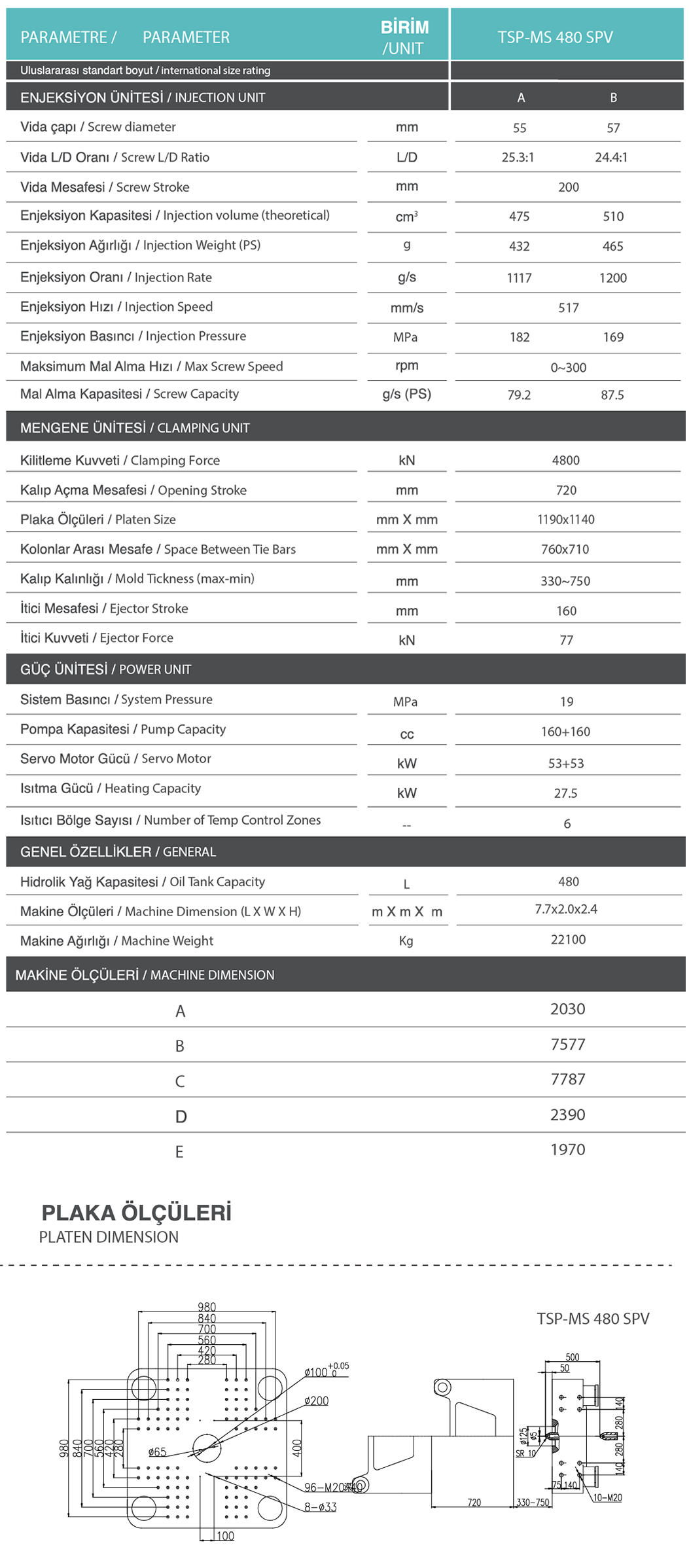

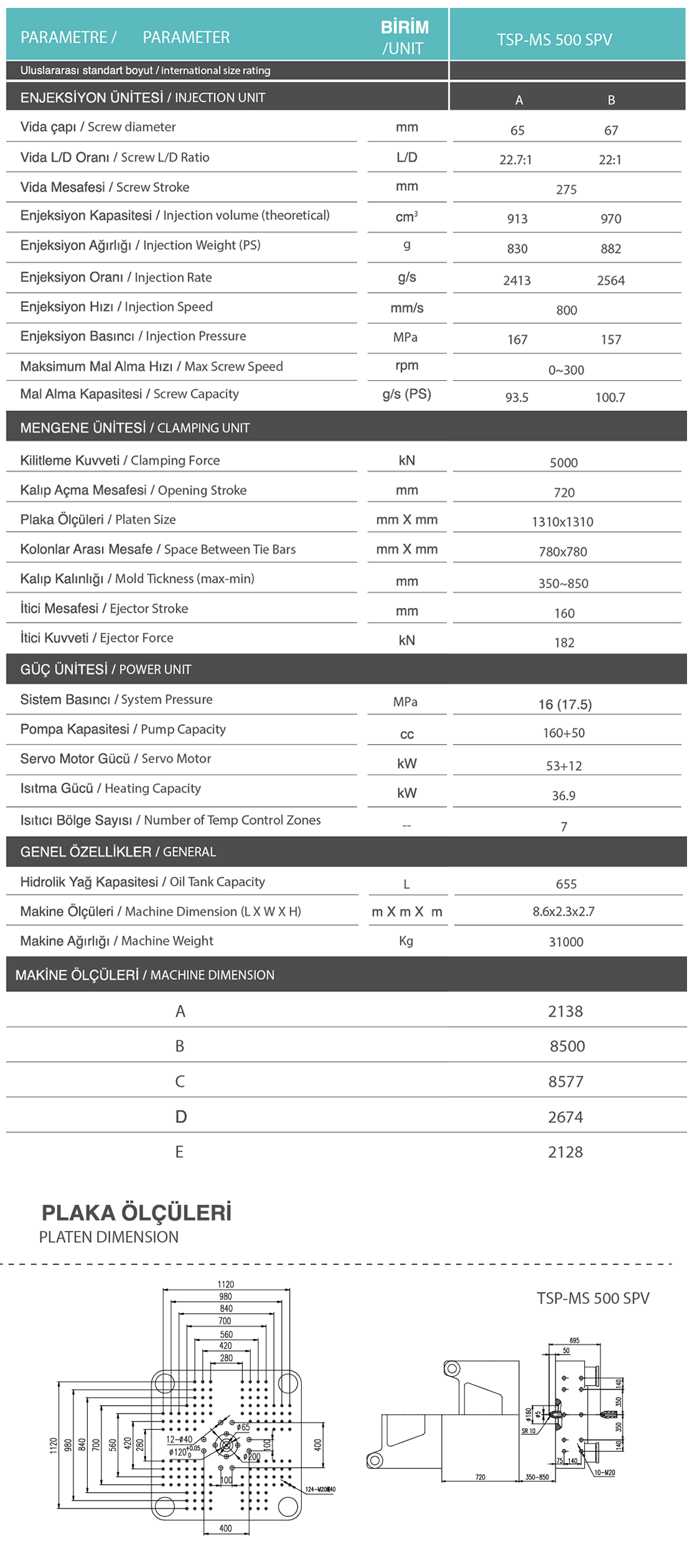

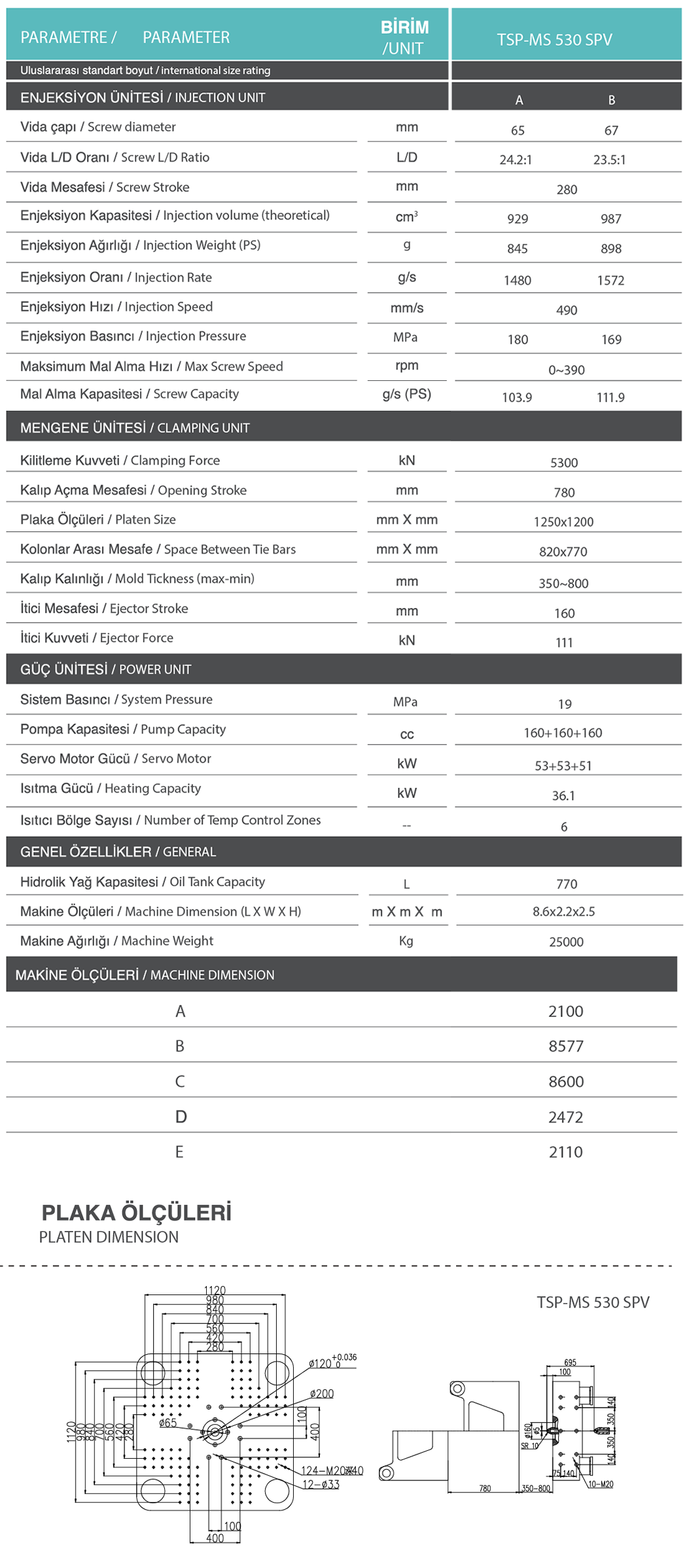

High-speed injection molding machine for thin-walled products. The SP series is available in a wide tonnage range, with options from 270 tons to 530 tons.

The new concept injection molding machine is designed to deliver a shorter cycle time for thin-walled products. It achieves this by integrating high-speed, low-pressure injection with multi-parallel movements, an optimized clamping and lubrication unit, and a revised hydraulic system.

Compared to conventional machines, this high-speed servo series prioritizes both cycle time and energy savings. It also enhances stability and service life by minimizing stress on the mechanical structure and hydraulic motors.

Injection Speed, Parallel motion, combined with high-speed, low-pressure injection, provides a shorter cycle time for thin-walled products.

Dual Piston Rod for the Injection Cylinder

Low-Friction Design, The injection unit, equipped with a linear guide, minimizes friction to increase speed.

Optional: The Swiss-made HERZOG pneumatic shut-off nozzle effectively prevents back suction.

Greater Energy Efficiency, Higher Speed, Enhanced Stability

Parallel motion significantly reduces the cycle time during material charging. This functionality is also available as an optional feature.

The high-performance control system, equipped with KEBA, features a large LCD screen and a user-friendly interface.