Raw Material Dryers, Cabinet Dryers, European Standard Raw Material Dryers, Energy-Saving Dryers, Dryer Spare Parts.

HHD Raw Material Dryer

OPTIONS

NOTE

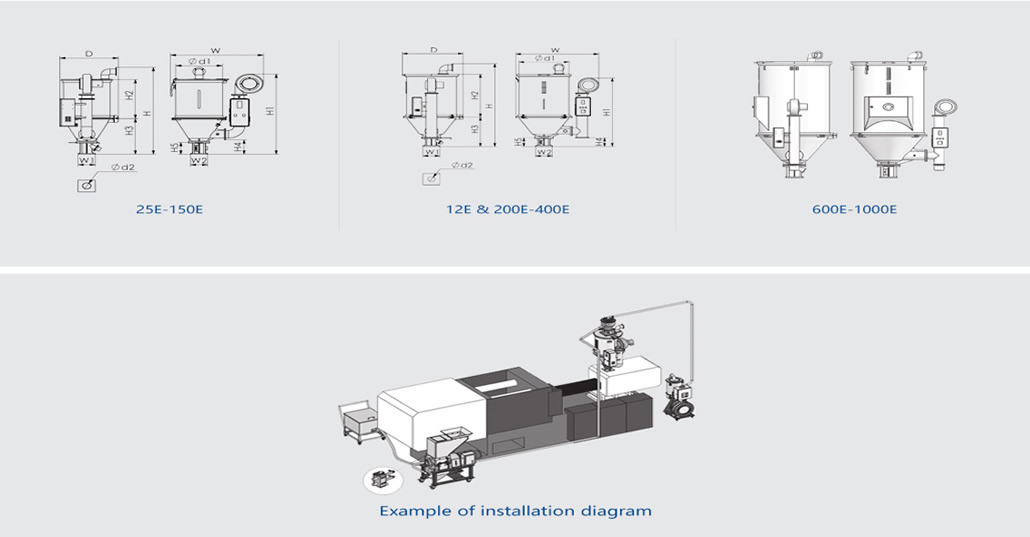

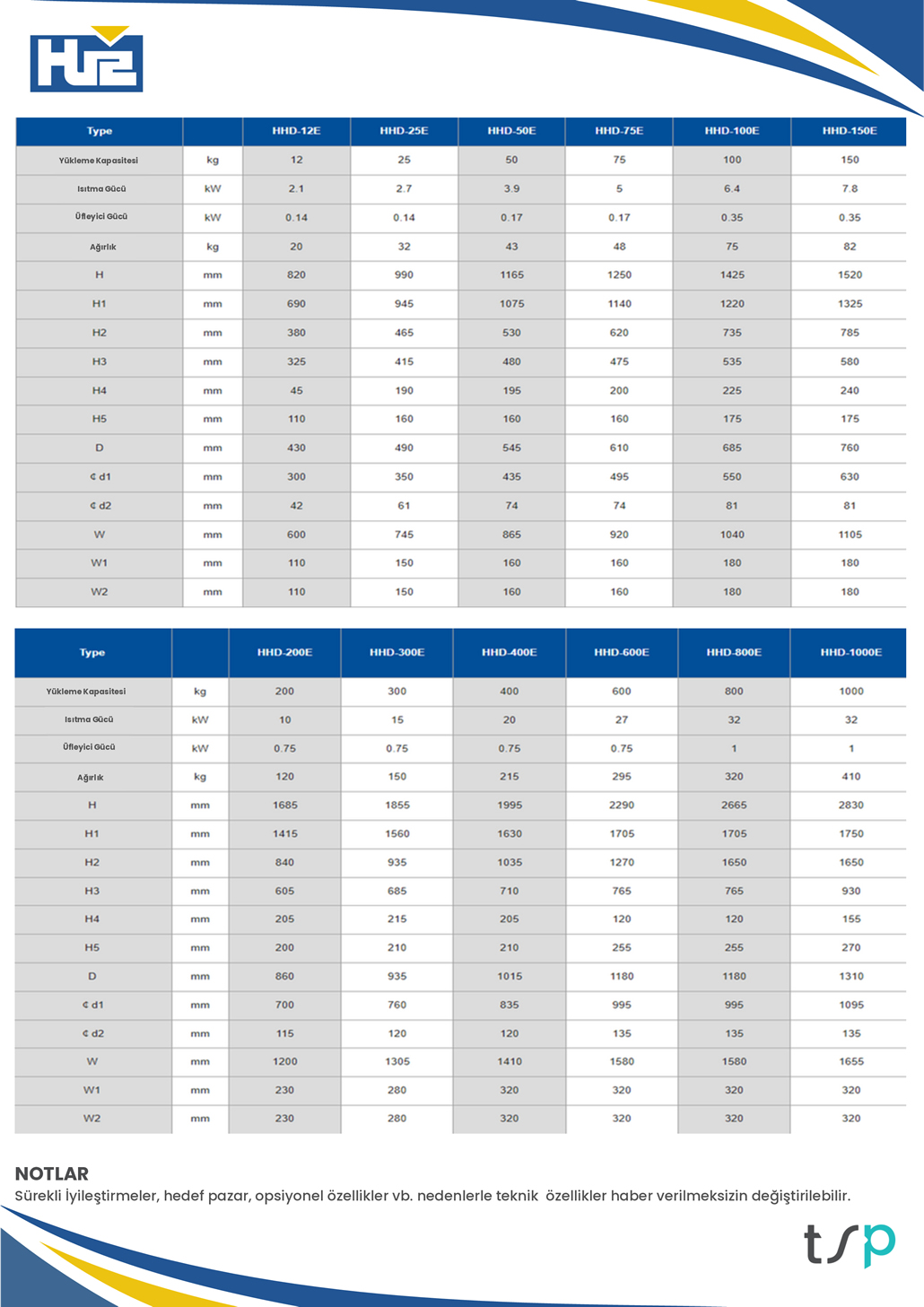

TECHNICAL DATA

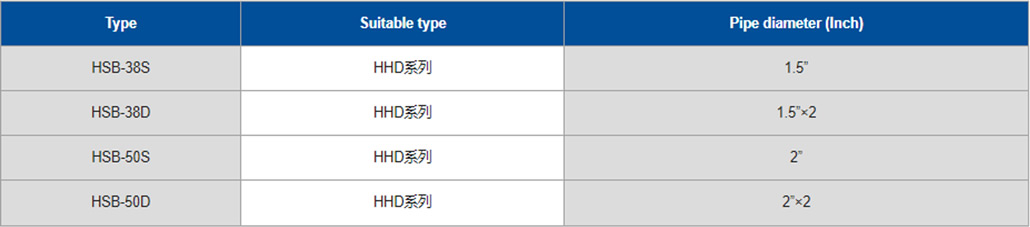

MODEL SELECTION

HCD Cabinet Dryer

Note

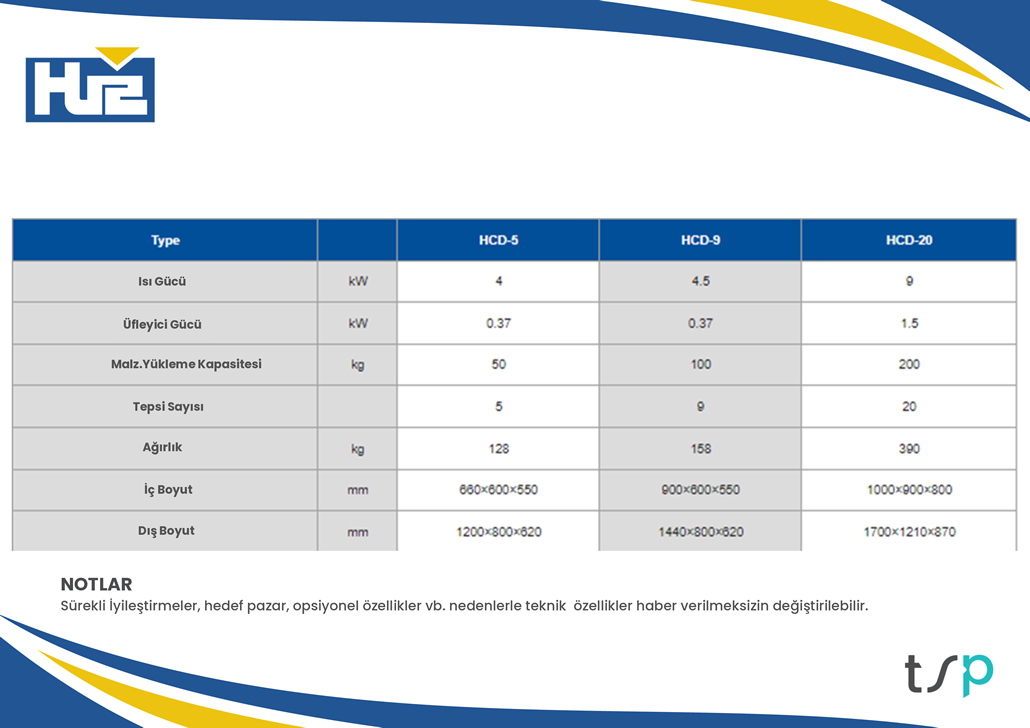

TECHNICAL INFORMATION

MODEL SELECTION

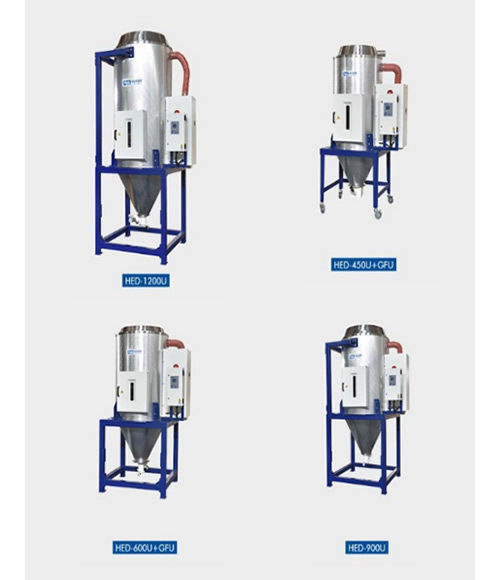

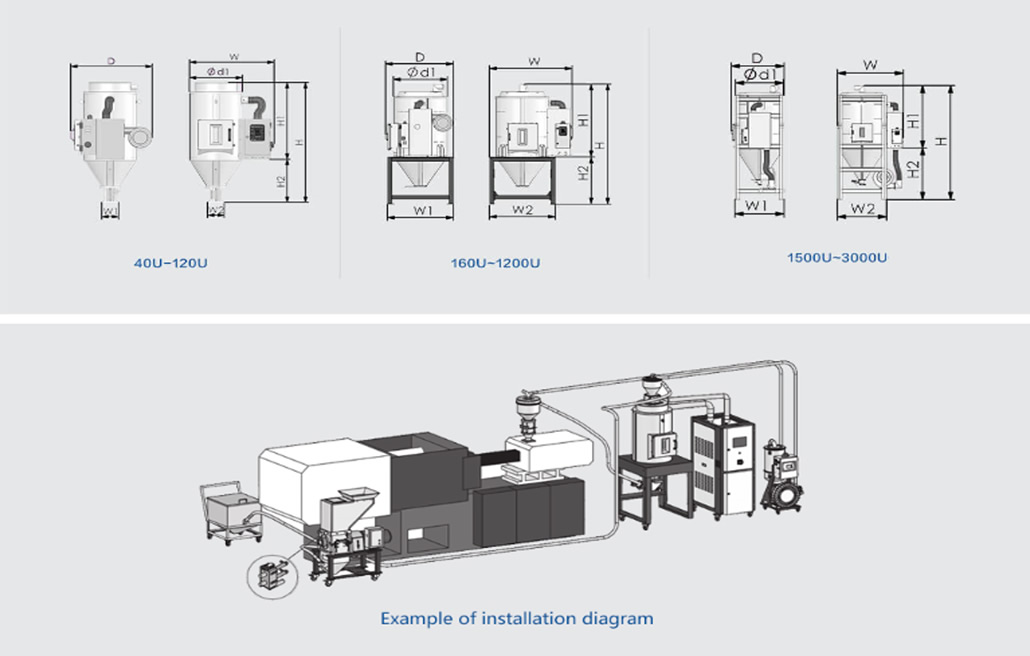

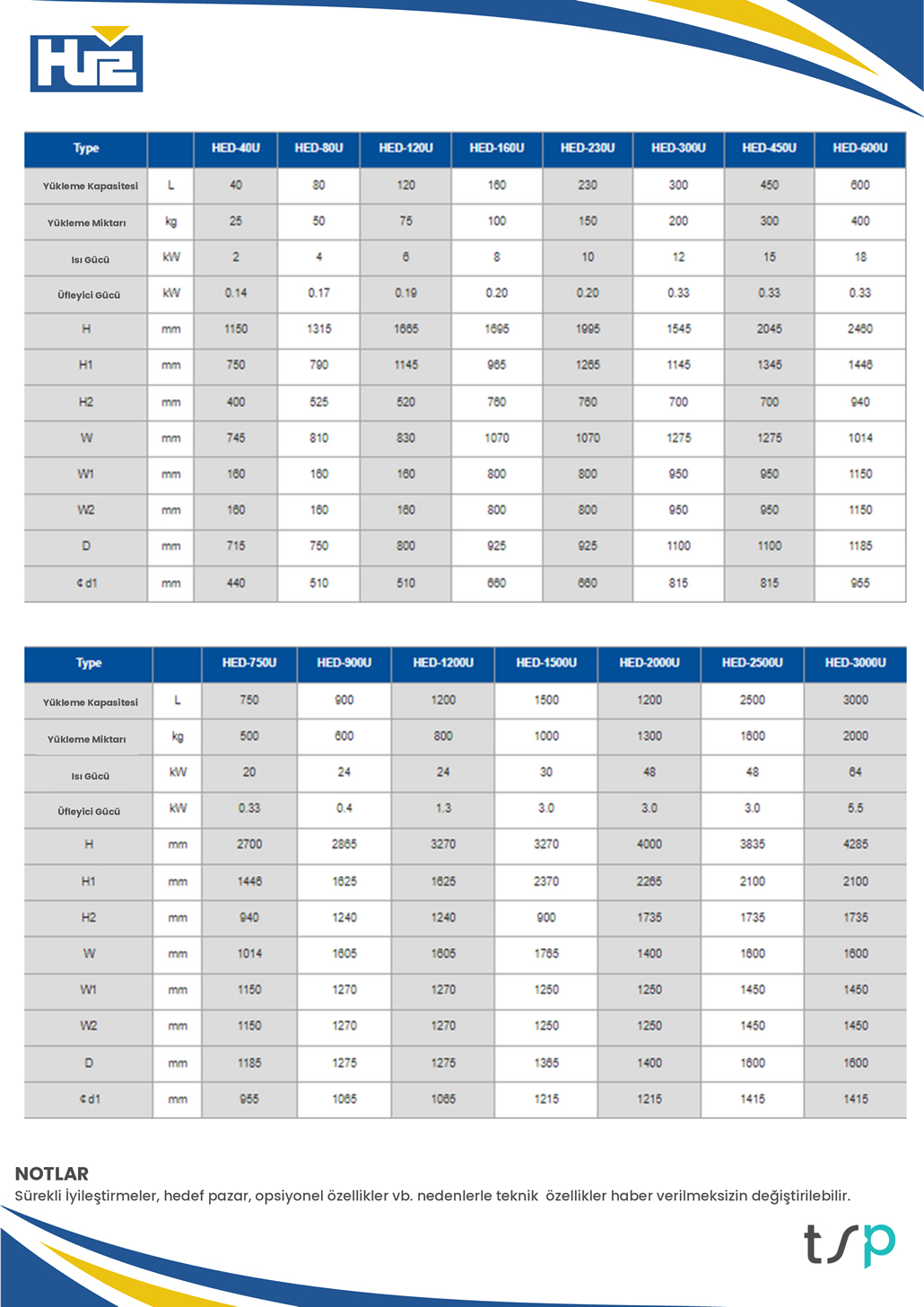

HED European Raw Material Dryer

OPTIONS

TECHNICAL INFORMATION

MODEL SELECTION

Special Features

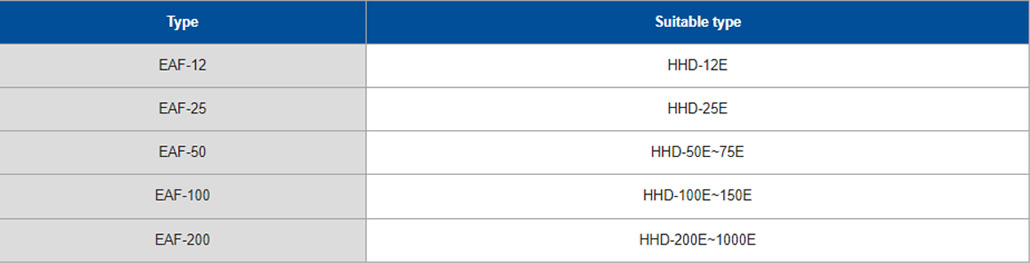

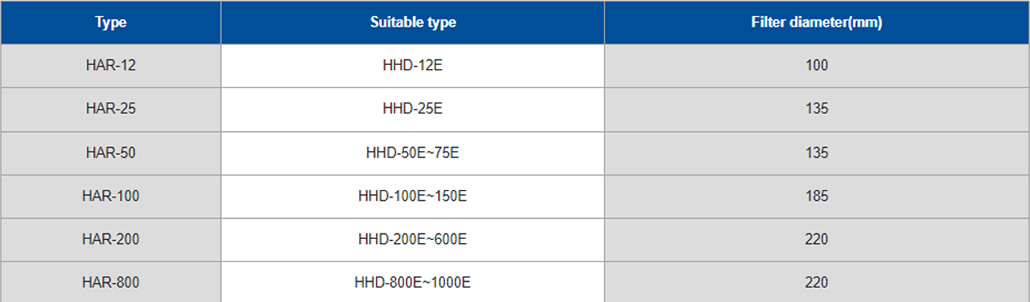

Dryer Filter

This device can effectively filter dust from the dryer exhaust to prevent air pollution, protect the environment, and provide up to 99% efficiency.

TECHNICAL DATA

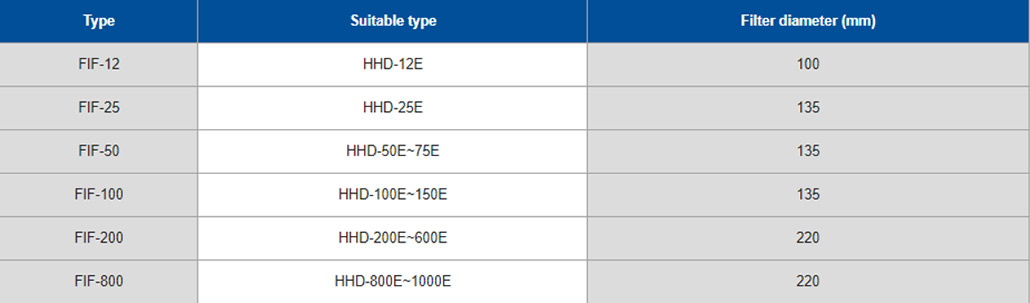

Fan Inlet Filter

The fan inlet filter improves the molding quality of transparent materials by keeping the dry raw materials clean. The air volume can be adjusted as needed.

TECHNICAL DATA

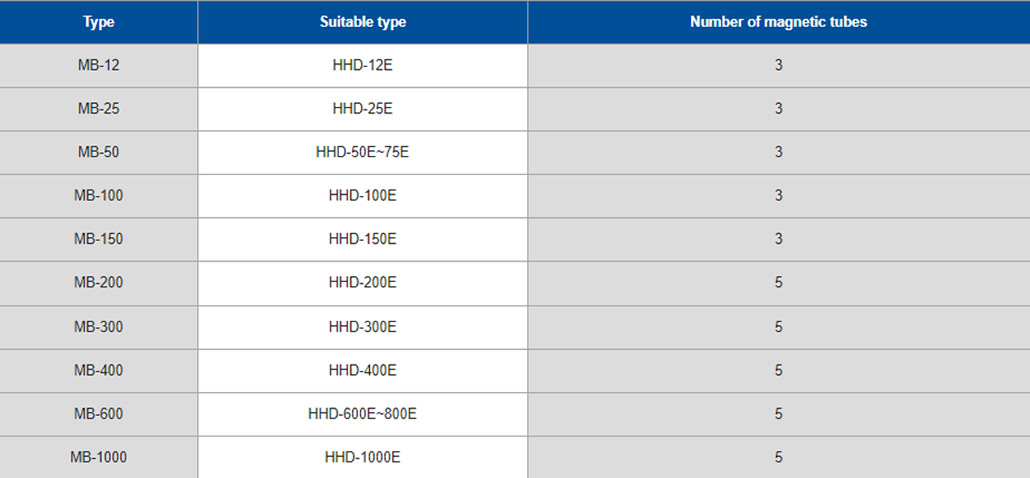

Dryer Throat with Magnet

Used as a magnetic guard for the screw feed inlet, it effectively removes and absorbs iron impurities from raw materials to prevent them from entering the furnace. It can be used together with the hopper magnetic frame to protect both the screw and the furnace.

TECHNICAL DATA

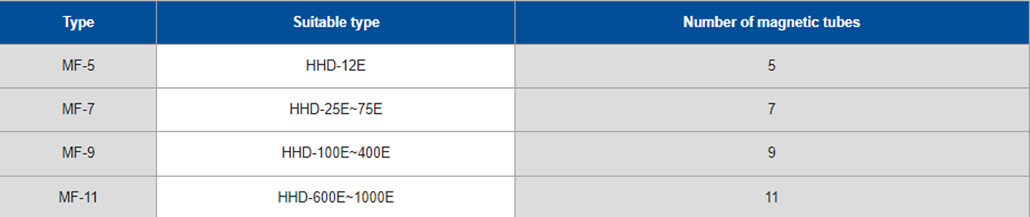

Magnet Inside the Dryer

It is used as a magnetic guard for the screw feed inlet. It effectively absorbs and removes iron impurities from raw materials to prevent them from entering the furnace, thereby protecting the screw and the furnace.

TECHNICAL DATA

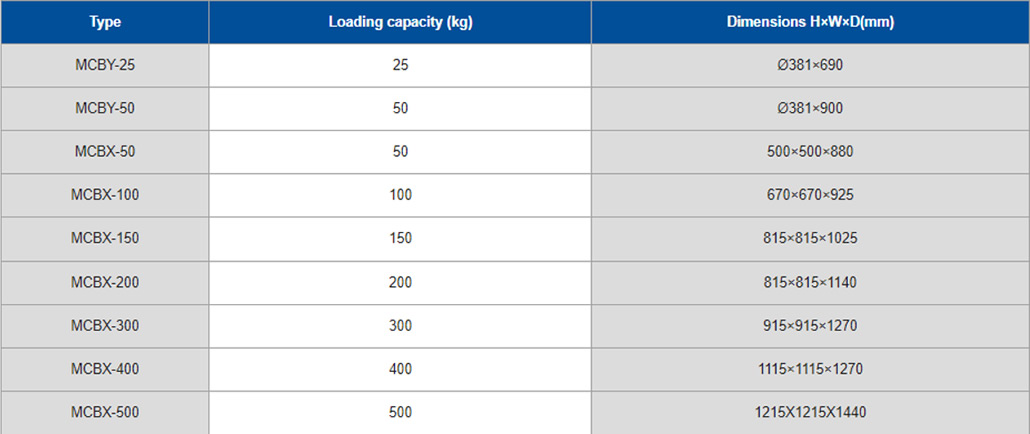

Raw Material Transfer Hopper

Used for the easy transportation of raw materials with wheels, it is designed to keep the materials clean.

TECHNICAL DATA

Hot Air Recycling

To ensure product quality, this device uses hot air recycling to reduce energy consumption, saving approximately 40% of energy.

TECHNICAL DATA

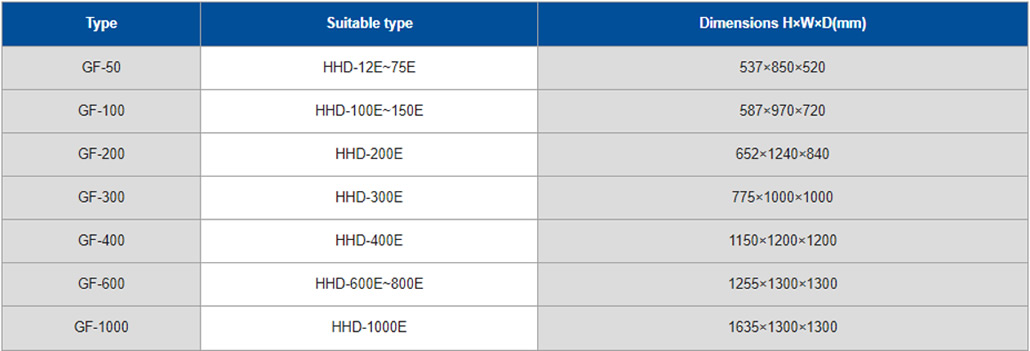

Ground Frame

When used on the floor, the hopper dryer can be mounted on this ground frame. The wheeled frame is easy to move, suitable for high-grade facilities, and can be easily supported by the machine.

TECHNICAL DATA

Suction Throat

When the feeder dryer is installed on a tripod, it can be supported by an automatic loader, which reduces manual labor and increases efficiency.

TECHNICAL DATA