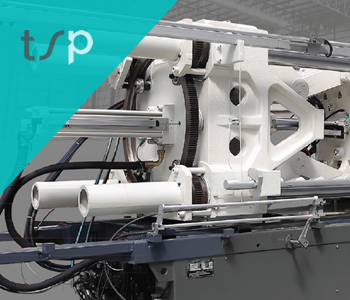

TSP WS Series

It provides the best and efficient performance in all kinds of injection processes with the advantages of a robust mechanical system, high precision and wide column spacing. WS offers options with a wide tonnage range from 100 tons to 2800 tons.